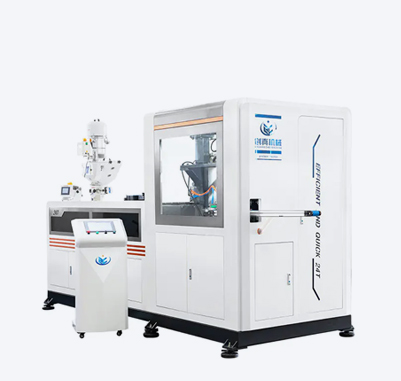

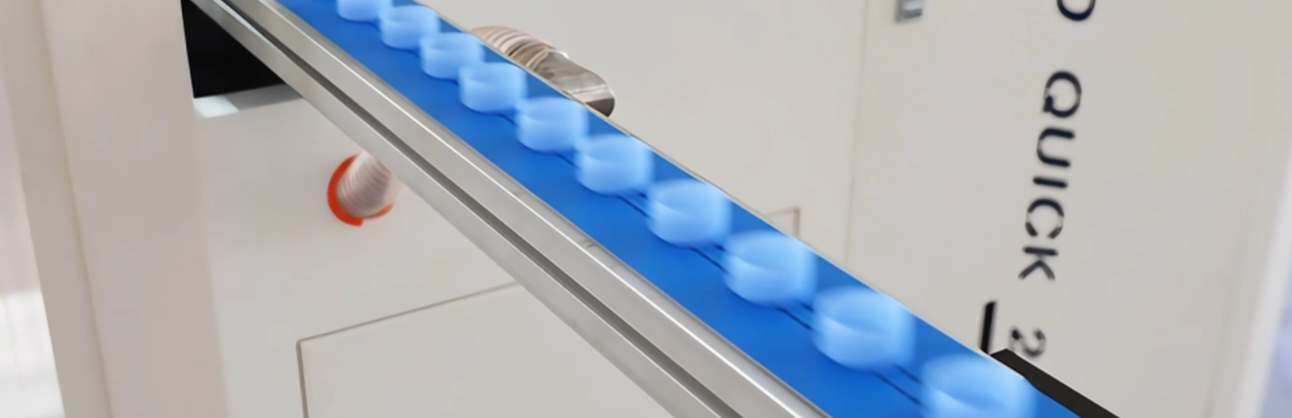

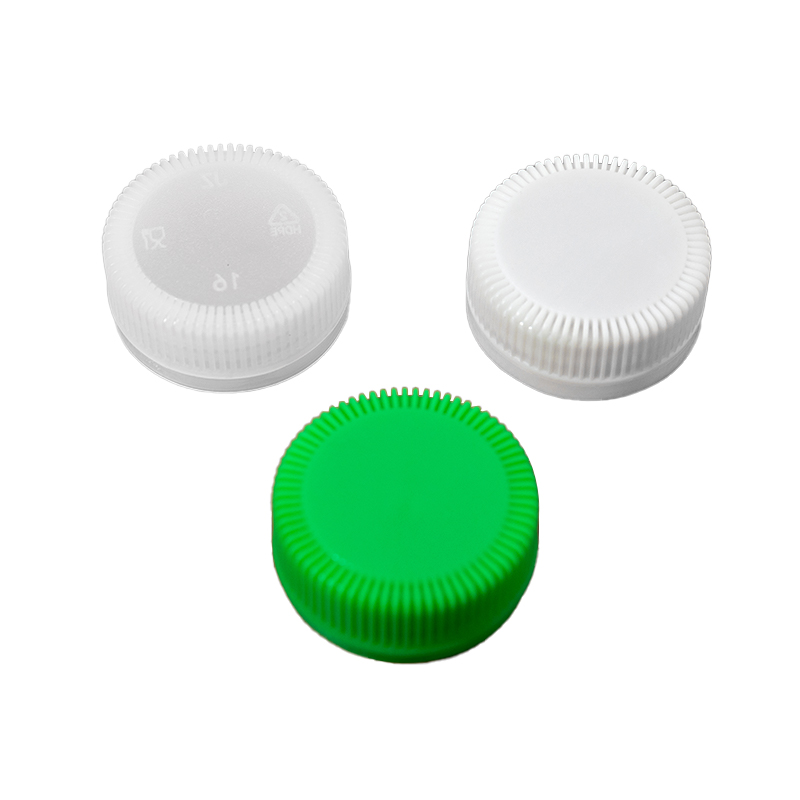

Our featured product is the high-speed cap compression molding machine, which adopts advanced control systems, efficient processing capabilities, and energy-saving technologies, bringing revolutionary upgrades to bottle capping systems.

-

Quality Inspection Team

The company strictly implements procedures such as screening and auditing of raw material suppliers, testing of incoming materials, and comparison of incoming materials. Advanced production process design and program control make each batch of products more stable and traceable, and production control is efficient.