chuangzhen@capping-machine.net

EN

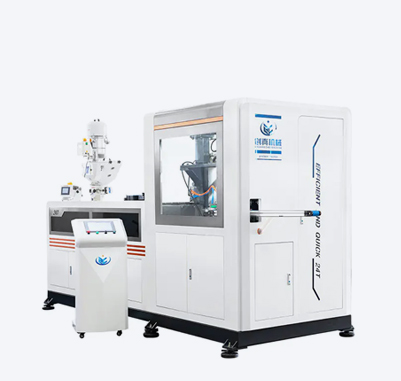

In today’s fast-evolving packaging industry, the demand for reliable, efficient, and high-quality cap production equipment is growing rapidly. Among the various technologies available, the Cap Compression Moulding Machine has become a preferred choice for many manufacturers, especially in industries such as beverages, daily chemicals, and pharmaceuticals. Its ability to produce consistent and smooth bottle caps has made it a valued asset on modern packaging lines.

A Cap Compression Moulding Machine operates by compressing melted raw material directly into a mould cavity, forming a cap through pressure rather than injection. This technique offers several advantages over traditional methods, which is why it continues to gain popularity across global markets. One of the primary reasons companies adopt this equipment is that compression-moulded caps display a clean and uniform appearance without injection dots, enhancing the overall visual appeal of the final product.

An important feature of the Cap Compression Moulding Machine is its multi-mould rotating production system. This design allows multiple caps to be formed simultaneously as the mould disc rotates. By enhancing the number of cavities and optimising cycle times, it ensures stable and high-capacity cap production suitable for busy packaging lines. The ability to maintain consistent output while keeping defect rates low makes this technology particularly valuable for manufacturers handling large-volume orders.

Modern Cap Compression Moulding Machines are equipped with advanced hydraulic and servo control systems. These systems play a critical role in guaranteeing precise movement and reliable operation throughout the compression process. The servo control technology, in particular, ensures smooth, steady, and controlled mould closing and opening actions, reducing mechanical stress on the equipment and extending its service life.

Another notable characteristic of the Cap Compression Moulding Machine is its unique pneumatic ejection system. Instead of relying on mechanical ejectors, it uses a rotating pneumatic mechanism to remove the caps from the moulds after formation. This design reduces the risk of damaging the cap thread and maintains the integrity of each produced cap, which is essential for maintaining a tight seal and reliable bottle closure in downstream applications.

The Cap Compression Moulding Machine also stands out for its compact, space-saving structure and automatic operation. It seamlessly integrates into modern packaging lines without occupying excessive floor space, which is a valuable advantage for factories aiming to optimise their production area. Its automatic controls reduce the need for constant human supervision, contributing to operational efficiency and consistent product quality.

Ease of maintenance and quick adaptability to different production demands are additional strengths of the Cap Compression Moulding Machine. Operators can conveniently switch raw materials and moulds without complex procedures or long downtime. This flexibility makes it suitable for packaging manufacturers producing various cap sizes and designs to meet diverse market needs.

On modern production lines, the Cap Compression Moulding Machine contributes to both product consistency and operational productivity. Its high-speed operation capability ensures that bottle caps are produced in large quantities without sacrificing appearance or functional standards. Moreover, the controlled forming conditions provided by the machine result in caps with stable dimensions, reliable sealing performance, and good thread precision — all of which are vital in safeguarding product integrity during packaging, transportation, and storage.

The combination of multi-mould rotating production, advanced hydraulic and servo systems, pneumatic ejection, and easy operation makes the Cap Compression Moulding Machine a trusted choice for cap production workshops worldwide. Its capacity to handle different materials and cap designs further enhances its versatility in modern manufacturing environments.

As the packaging industry evolves, driven by consumer needs and market trends, equipment like the Cap Compression Moulding Machine remains important for producing consistent, high-volume, and attractive caps. Taizhou Chuangzhen Machinery Manufacturing Co., Ltd., based in Chengjiang Industrial Zone, Huangyan District, Taizhou City, Zhejiang Province, provides customers with efficient, high-quality bottle cap production lines. Their automatic cap forming machines are used for a wide range of plastic bottle caps, including those for mineral water, carbonated drinks, juices, cosmetics, medical supplies, edible oils, and liquor.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.