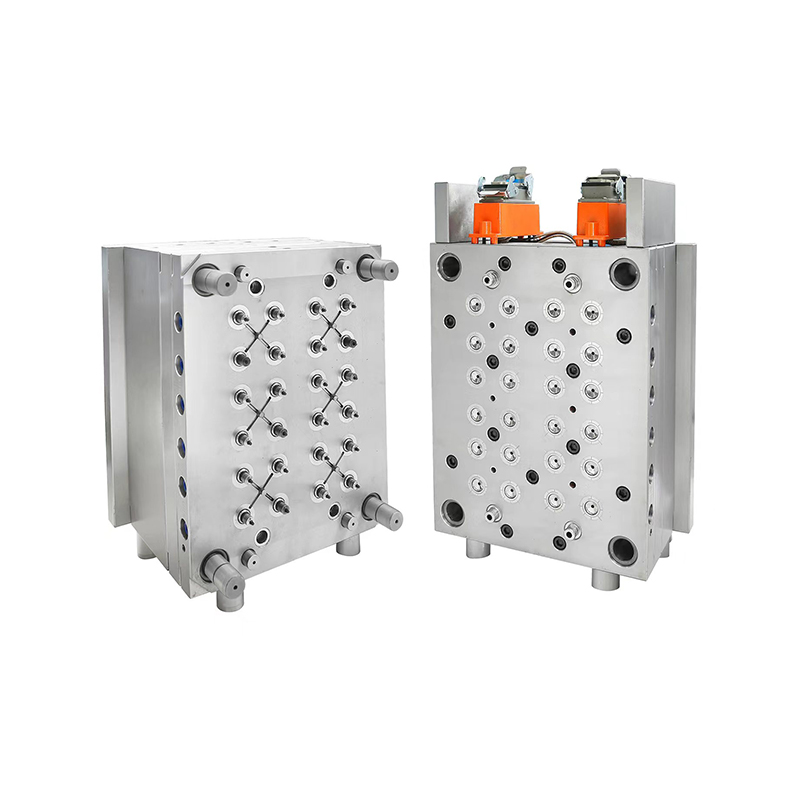

The 24 Cavity Cap Mould is an advanced injection moulding solution designed for high-volume production of caps with prec...

chuangzhen@capping-machine.net

EN

chuangzhen@capping-machine.net

EN

Cap moulds are integral components in the manufacturing of plastic caps used across various industries, including beverage, pharmaceutical, and personal care products. These moulds must meet stringent requirements to ensure high-quality production and durability. This article delves into the materials, design, and processing techniques that contribute to the exceptional performance of cap moulds.

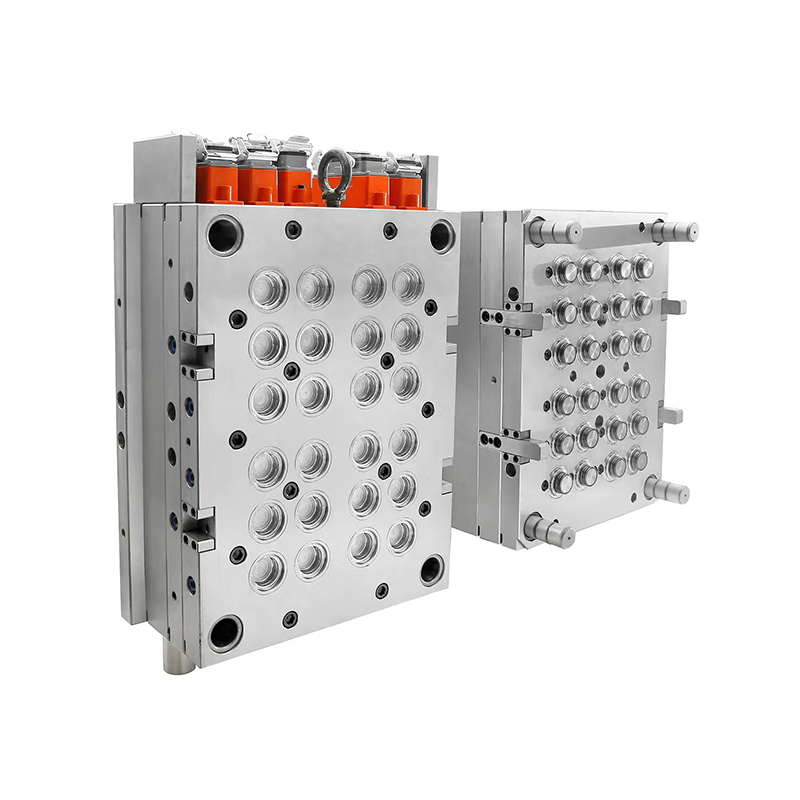

The primary material for cap moulds is a proprietary blend designed for outstanding wear and corrosion resistance. This material stands out due to its optical polishing activity, which is crucial for achieving smooth and precise cap surfaces. Additionally, the material boasts good machinability and quench stability, making it ideal for complex mould designs that require high precision and durability.

Alloy steel braces are incorporated into cap moulds to enhance their hardness and wear resistance. This type of steel is renowned for its ability to withstand high stress without deforming or burning, ensuring the mould's longevity even under continuous use. The combination of the proprietary material and alloy steel braces results in a robust mould capable of maintaining its integrity over extended periods.

The cap moulds feature a specialized coating provided by a Swiss company. This coating is applied to the steel at a precise thickness, ensuring a strong bonding force that enhances the mould's hardness while reducing friction and wear. The coating technology effectively extends the mould's lifespan by two to six times compared to uncoated moulds. The lower friction and reduced wear also contribute to consistent product quality and reduced maintenance needs.

To further enhance the durability of cap moulds, hardening heat treatment is carried out. This process ensures that the moulds achieve a Rockwell hardness of 58-60 HRC, providing exceptional strength and wear resistance. The heat treatment process is carefully controlled to reduce distortion, ensuring that the moulds retain their precise dimensions and structural integrity.

The stringent standards adhered to during the hardening process cover various aspects, including material quality, appearance, deformation degree, and hardness. This comprehensive approach guarantees that each cap mould meets the higher quality benchmarks, contributing to consistent performance and reliability in production.

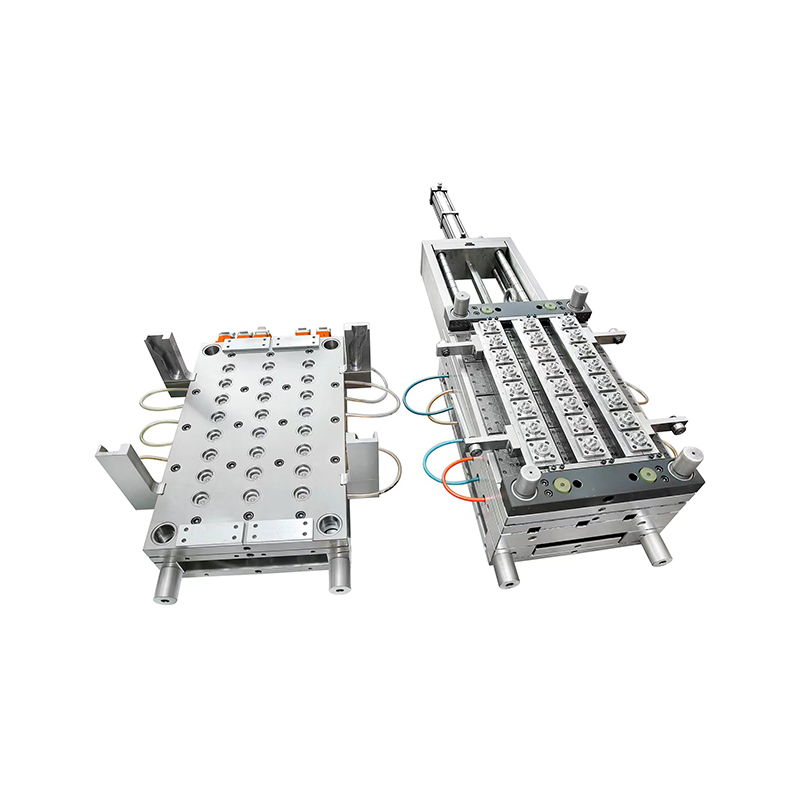

All cap moulds undergo processing in advanced Foreign CNC centres, which ensures high precision and consistency. The final accuracy of these moulds typically reaches 2-3 micrometres, meeting the stringent size tolerance requirements for bottle caps. This level of precision is crucial for ensuring that caps fit securely and function correctly, thereby maintaining the quality and safety of the end products.

Cap moulds are designed with several optimized features to enhance their performance and efficiency. These include:

Hot Runner System: The hot runner system is optimized to ensure uniform temperature distribution and efficient material flow. This reduces waste and improves the consistency of the caps produced.

Cooling System: An efficient cooling system is integrated into the mould design to reduce cycle times and improve production efficiency. The cooling system helps maintain the mould's temperature, preventing overheating and ensuring consistent cap quality.

Preform Design: The preform design is optimized for weight, stretching ratios, and material distribution. This ensures that each cap is produced with less material waste while maintaining structural integrity and performance.

Weight and Wall Thickness Tolerance: The moulds are designed to achieve less weight and wall thickness tolerances, ensuring consistent cap quality and reducing material usage.

Valve Gate Hot Runner System: The valve gate hot runner system eliminates the need for manual tail cutting, improving production efficiency and reducing labour costs.

The cap moulds are made from high-quality imported mould steel, specifically ASSAB S136 and Germany 2316. These materials are chosen for their properties, including high corrosion resistance, wear resistance, and polishability. The use of these premium steels ensures that the cap moulds can withstand the rigours of high-volume production while maintaining their performance and durability.

Cap moulds are critical components in the production of plastic caps, requiring precise design, high-quality materials, and advanced processing techniques. The use of proprietary materials, alloy steel braces, specialized coatings, and hardening heat treatments ensures that these moulds deliver exceptional performance and longevity. Precision CNC processing and optimized design features further enhance the moulds' efficiency and effectiveness, making them indispensable in various industries.

By adhering to stringent quality standards and incorporating advanced technologies, manufacturers can produce cap moulds that consistently meet the high demands of modern production environments. These moulds not only improve the quality of the caps produced but also contribute to overall production efficiency and cost-effectiveness.

The 24 Cavity Cap Mould is an advanced injection moulding solution designed for high-volume production of caps with prec...

Our 24 cavity plastic cap mould represents precision engineering and innovation in mould manufacturing. and innovation i...

Product Overview: 8-Cavity Cap MouldOur 8-cavity cap mould represents precision engineering and advanced manufacturing t...

Introducing the 8 Cavity Cap Mould crafted from premium mould steels ASSAB S136 and Germany 2316, meticulously designed ...

At our manufacturing facility, we take pride in delivering precision-engineered moulds that meet the higher industry sta...

Our 24 Cavity PP Cap Mould represents a pinnacle in precision engineering and innovation, designed to meet the demanding...

Product Capacity

Exporting Country

Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. is a professional and , main products are plastic bottle cap forming machines, folding machines, cutting machines, etc. The companies adhere to the "customer-oriented, forge ahead" business philosophy to provide our customers with quality service.

The company provides our customers with efficient, high-quality bottle cap production lines. Our automatic bottle cap forming machines are used to produce a wide variety of plastic bottle caps, primarily for mineral water bottles, carbonated beverages, hot juices, daily necessities, cosmetics bottles, medical supplies, edible oils, and a variety of liquor caps. The machine consists mainly of 16-48 cavities, the die is multi-purpose and simple to operate, and the machine parts and other accessories are provided by world-renowned manufacturers to ensure the stable operation of the machine so that they can truly realize their automation and high efficiency in bottle cap production. Automatic cap machines can produce up to 1,000.000 units per day, effectively saving labor and space costs, and high efficiency and energy savings benefit your short-term recovery costs and profits.

Negotiations are welcome with our company. We will provide a high-quality, thoughtful service to meet your needs.

Learn about our industry exhibition information and recent events in our company.

The recent shipment of a full high-speed production line has highlighted the manufacturing strength behind the High Speed Cap Compression Molding Machine, refl...

Capping Machine represent one of the final critical steps in many packaging lines. They apply screw caps, snap-on lids, press-on closures, roll-on bands, and va...

Bottle caps keep household cleaners from leaking onto shelves, stop garden pesticides from evaporating in the garage, and prevent brake fluid from spilling duri...

Bottle caps secure the contents of containers and allow users to open them when needed. A liner inside the cap presses against the bottle neck to form a seal th...