Our PLC Full automatic High Speed Slitting Machine is a piece of equipment designed to streamline the production process...

chuangzhen@capping-machine.net

EN

chuangzhen@capping-machine.net

EN

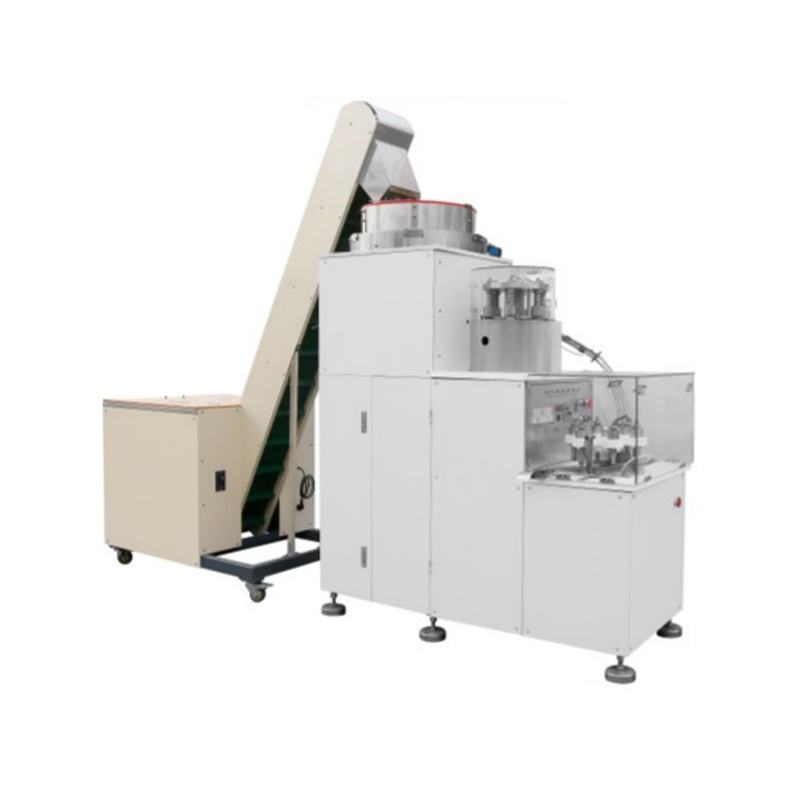

In the world of modern manufacturing, efficiency, and precision are crucial. The Full-Automatic High-Speed Cap Slitting Machine is a piece of equipment designed to streamline the production process for manufacturers dealing with cap production. This machine integrates a series of automatic procedures including increasing, sorting, transmitting, separating caps, and detaching boxes, thereby facilitating a seamless assembly line process. Additionally, its heated blade technology ensures enhanced durability, making it a valuable asset for any production facility.

The Full-Automatic High-Speed Cap Slitting Machine is designed for use in industries where cap production is a significant part of the manufacturing process. This includes sectors like beverages, pharmaceuticals, cosmetics, and other consumer goods. The machine's primary function is to create anti-theft rings on caps, which is an essential feature for many products to ensure tamper-evidence and consumer safety. Its versatility allows it to handle various cap sizes and types, making it suitable for a wide range of applications. By automating the slitting process, the machine significantly reduces manual labor requirements, thereby improving production efficiency and consistency.

The production process with the Full-Automatic High-Speed Cap Slitting Machine is both efficient and streamlined. The machine is designed to handle the entire procedure automatically, from the initial stages of sorting and transmitting caps to the final stages of slitting and separating them. The process begins with the caps being fed into the machine, where they are sorted and aligned correctly. The heated blade then slits the anti-theft rings with high precision, ensuring each cap meets the required specifications. The sorted and slit caps are then transmitted to the next stage of production or packaged directly, depending on the setup. The integration of these processes into one continuous workflow reduces downtime and improves productivity.

To ensure efficient performance and longevity, the Full-Automatic High-Speed Cap Slitting Machine requires regular maintenance and service. The machine is designed with user-friendly interfaces and automated diagnostic features that simplify troubleshooting and upkeep. Scheduled maintenance includes checking and calibrating the heated blade, lubricating moving parts, and inspecting the sorting and transmitting mechanisms for any signs of wear. The manufacturer provides comprehensive service support, including technical assistance, spare parts, and training for operators. This robust service framework ensures that the machine remains in good operating condition, thereby reducing the risk of unexpected breakdowns and prolonging its service life.

Advantages

The Full-Automatic High-Speed Cap Slitting Machine offers several key advantages that make it an indispensable tool for modern manufacturing:

Fast Speed of Slitting Anti-Theft Rings: The machine operates at a high speed, significantly increasing the throughput of cap production. This rapid processing capability ensures that large volumes of caps can be produced in a short time, meeting the demands of high-production environments.

Full Automation and Ease of Operation: One of the standout features of the machine is its full automation. It is designed to handle the entire process with less human intervention, from sorting and aligning caps to slitting and packaging. The user-friendly interface makes it easy to operate, reducing the need for extensive operator training and allowing for quick adjustments as needed.

Stable and Accurate Running: The machine is engineered for stability and precision. Its robust construction and advanced control systems ensure that it runs smoothly and consistently, producing high-quality caps with precise anti-theft rings. This reliability is crucial for maintaining product standards and avoiding costly production errors.

High Quality and Cost Efficiency: The machine's heated blade technology not only enhances durability but also ensures clean and accurate slits, which are essential for the functionality of the anti-theft rings. Additionally, the automation and efficiency of the machine to significant cost savings in terms of labor and material waste. Over time, these savings can contribute to a substantial reduction in overall production costs.

The Full-Automatic High-Speed Cap Slitting Machine represents a significant advancement in cap production technology. Its application across various industries, streamlined production process, robust service and maintenance support, and numerous advantages make it an invaluable addition to any manufacturing operation. By integrating cutting-edge automation and precision engineering, this machine helps manufacturers achieve higher efficiency, consistency, and cost-effectiveness in their production lines.

Our PLC Full automatic High Speed Slitting Machine is a piece of equipment designed to streamline the production process...

The Waterfall Type Auto Cap Slitting Folding Machine represents a breakthrough in the realm of bottle cap manufacturing,...

The CZ-ZQ 20000 caps Auto Cap Folding-Cutting Machine represents an advanced solution in automated cap manufacturing, in...

Introduction to the Anti-theft Automatic Folding MachineThe Anti heft Automatic Folding Machine represents a breakthroug...

The Auto Cap Folding-Cutting Machine represents a significant advancement in the automation of bottle cap production pro...

Product Capacity

Exporting Country

Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. is a professional and , main products are plastic bottle cap forming machines, folding machines, cutting machines, etc. The companies adhere to the "customer-oriented, forge ahead" business philosophy to provide our customers with quality service.

The company provides our customers with efficient, high-quality bottle cap production lines. Our automatic bottle cap forming machines are used to produce a wide variety of plastic bottle caps, primarily for mineral water bottles, carbonated beverages, hot juices, daily necessities, cosmetics bottles, medical supplies, edible oils, and a variety of liquor caps. The machine consists mainly of 16-48 cavities, the die is multi-purpose and simple to operate, and the machine parts and other accessories are provided by world-renowned manufacturers to ensure the stable operation of the machine so that they can truly realize their automation and high efficiency in bottle cap production. Automatic cap machines can produce up to 1,000.000 units per day, effectively saving labor and space costs, and high efficiency and energy savings benefit your short-term recovery costs and profits.

Negotiations are welcome with our company. We will provide a high-quality, thoughtful service to meet your needs.

Learn about our industry exhibition information and recent events in our company.

The recent shipment of a full high-speed production line has highlighted the manufacturing strength behind the High Speed Cap Compression Molding Machine, refl...

Capping Machine represent one of the final critical steps in many packaging lines. They apply screw caps, snap-on lids, press-on closures, roll-on bands, and va...

Bottle caps keep household cleaners from leaking onto shelves, stop garden pesticides from evaporating in the garage, and prevent brake fluid from spilling duri...

Bottle caps secure the contents of containers and allow users to open them when needed. A liner inside the cap presses against the bottle neck to form a seal th...