-

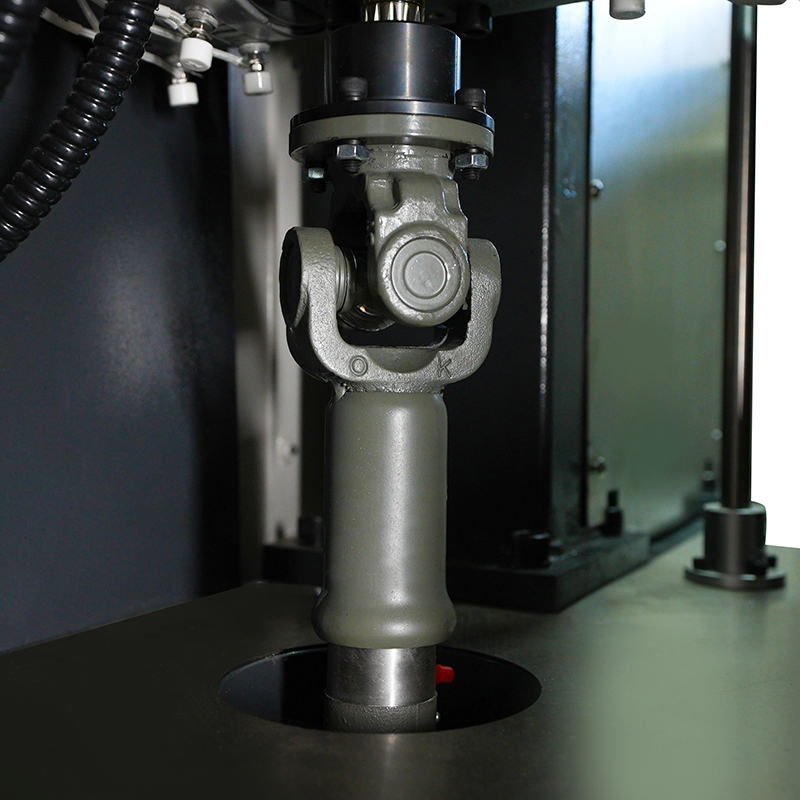

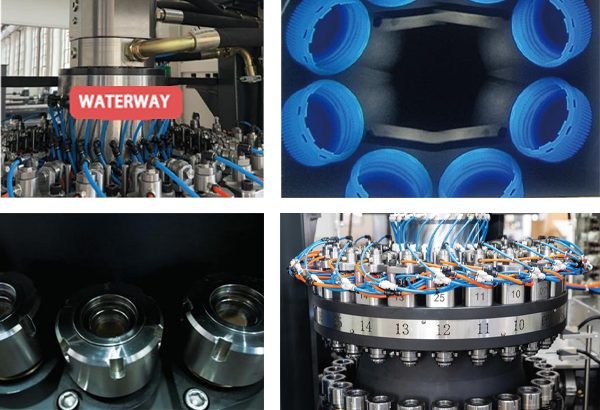

Material

The main cover mold material is made of proprietary material with excellent wear resistance, corrosion resistance and polishing properties, good machinability and quenching stability. The bracket is made of high-hardness, high wear resistance alloy steel, which is durable.

-

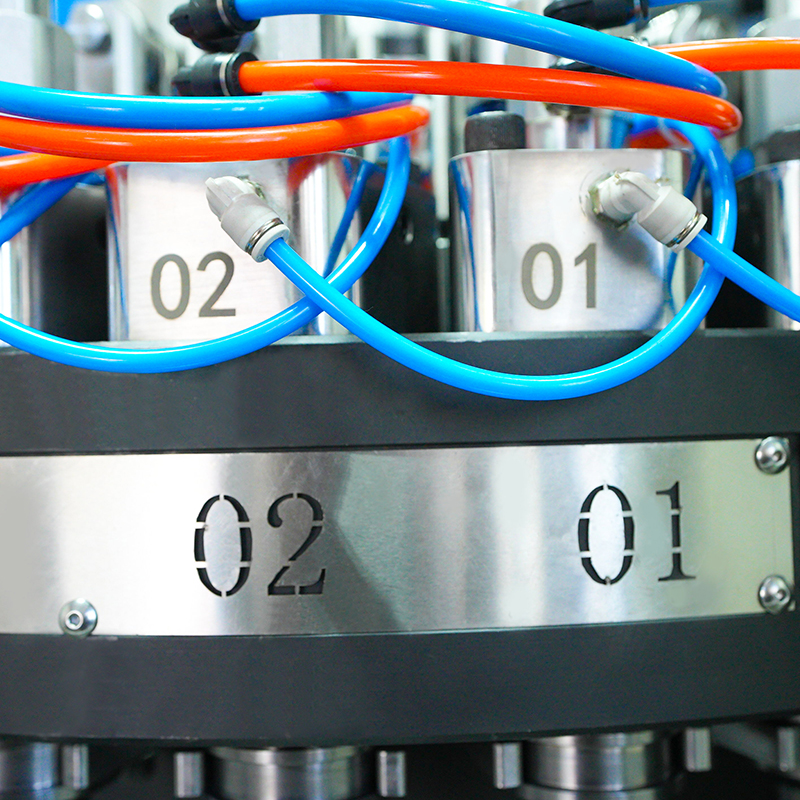

Coating

Cap mould specified coating by Swiss company, the coating thickness of thin steel, and strong bonding force, high hardness, lower friction and wear reducing, can effectively extend the use life of the molds 2-6 times.

-

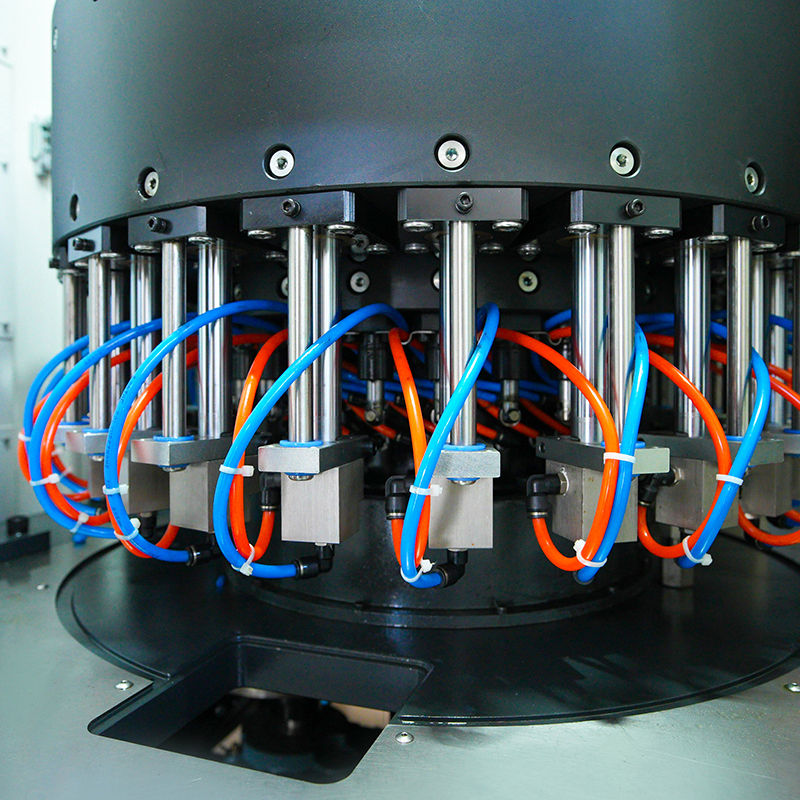

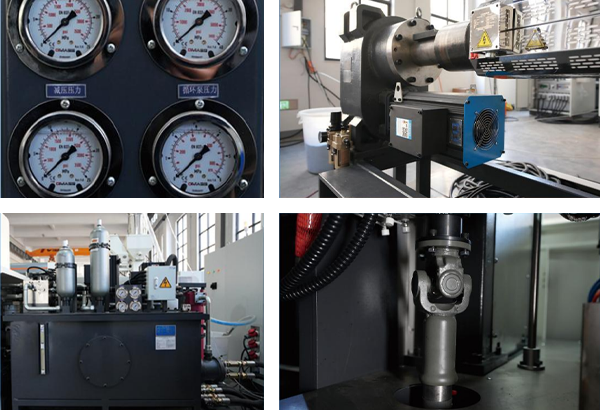

Hardening

We choose Sweden company to process the hardening heat treatment, the Rockwell hardness can reach 58- 60HRC after the step, while its small distortion of heat treatment. The company strict standard of the mold material, appearance, deformation degree,hardness and so on when process, and fully guarantee the quality of cap mold hardening.

-

Precision

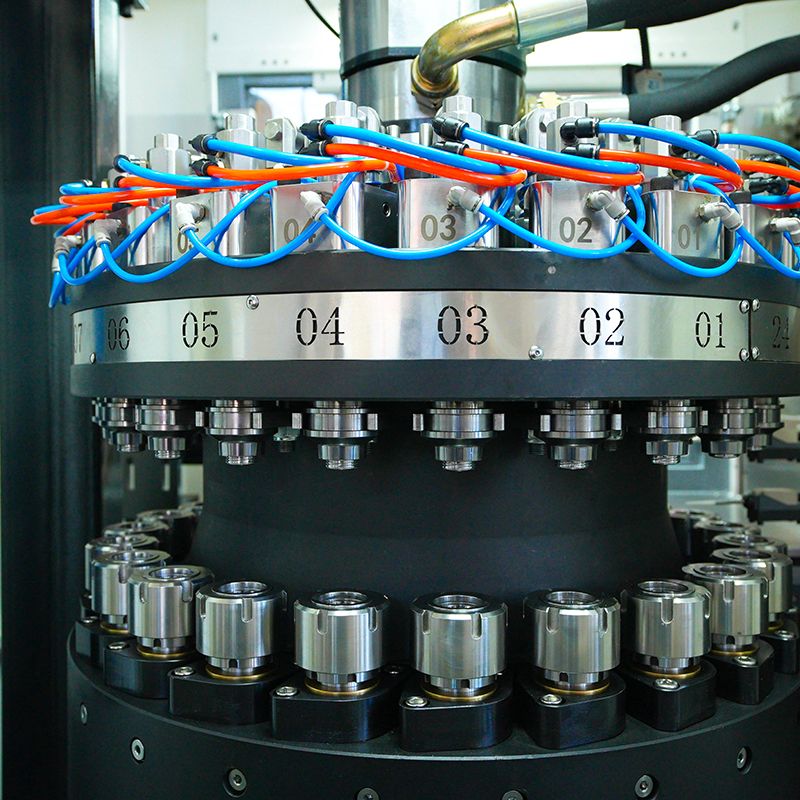

All molds processes by Foreign CNC centre, the final accuracy generally generally reached 2-3 2-3um, can effectively meet the requirements of size tolerance bottle, Chuangzhen's mold can achieve the requirements ofexchange.

chuangzhen@capping-machine.net

EN

中文简体

中文简体 русский

русский Español

Español عربى

عربى