chuangzhen@capping-machine.net

EN

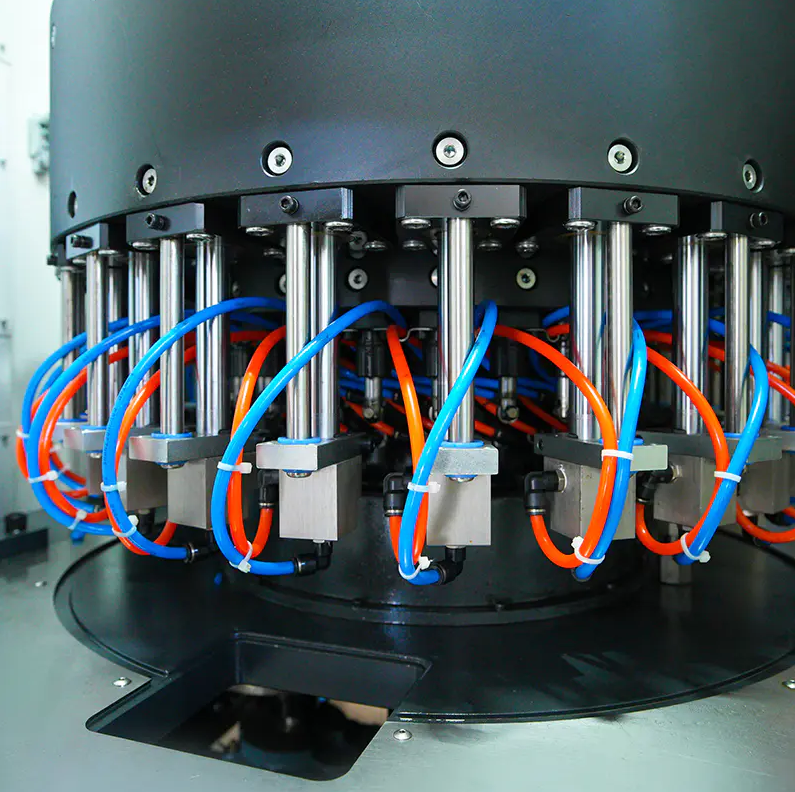

In modern manufacturing, the Cap Compression Molding Machine plays a vital role in enhancing efficiency and product quality within the packaging industry. Improvements in energy efficiency and the introduction of innovative materials have enabled manufacturers to produce caps faster while improving consistency, durability, and reducing environmental impact. These advancements address growing production needs while meeting increasing demands for sustainable manufacturing and high-quality packaging solutions.

Energy efficiency in modern molding begins with optimized heating systems and improved hydraulic circuits. Regenerative heating technology reduces energy consumption by recycling heat, while advanced control systems ensure precise temperature regulation. This precision minimizes waste and lowers operational costs, creating an environmentally responsible production process. Reduced energy consumption also aligns with stricter industry standards and sustainability objectives, making energy-efficient molding machines a strategic advantage for manufacturers.

Material innovation further enhances the performance of cap compression molding. Advanced polymers, high-performance resins, and engineered composites offer higher strength, elasticity, and chemical resistance. These materials help maintain structural integrity under pressure while resisting deformation over time. Such improvements extend product lifespan and allow more complex cap designs that meet diverse consumer and industry requirements. By integrating new materials with precise molding techniques, manufacturers can consistently deliver products that meet elevated quality and durability standards.

The synergy between energy-efficient designs and innovative materials also affects production speed and reliability. Modern machines feature high-precision molds that enable faster heating and cooling cycles. Combined with automated material handling and quick-change mold systems, these enhancements reduce downtime and support flexible production. Manufacturers benefit from the ability to adjust production lines quickly to meet evolving market needs without sacrificing efficiency or quality.

Automation plays a key role in these advancements. Programmable logic controllers (PLC) and human-machine interfaces (HMI) allow operators to control cycle time, temperature, and pressure, ensuring consistent results throughout production. Digital monitoring and process optimization tools further improve productivity by identifying maintenance needs and optimizing machine performance in real time. This minimizes unexpected downtime and maintains smooth operations.

Sustainability is another important aspect of modern cap compression molding. New materials are designed for recyclability and reduced environmental impact, while energy-efficient processes lower overall resource consumption. This combination contributes to ecological responsibility and cost efficiency. Manufacturers adopting these technologies enhance competitiveness and support the global shift toward greener production practices.

In applications such as beverage and pharmaceutical packaging, these improvements are particularly valuable. Consistent cap quality ensures product safety, maintains brand standards, and builds consumer trust. Faster production cycles allow manufacturers to meet surges in demand effectively, while durable materials ensure longevity during storage and transport.

Zhejiang Chuangzhen Machinery integrates energy efficiency with advanced material technologies, innovation in the cap compression molding field. Its equipment helps manufacturers produce high-quality caps quickly, sustainably, and reliably. By focusing on precision engineering and sustainable solutions, Chuangzhen Machinery supports the industry in advancing toward greater efficiency, durability, and environmental responsibility.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.