chuangzhen@capping-machine.net

EN

In the ever-evolving packaging industry, Capping Machines have become an essential part of ensuring the efficiency and reliability of production lines. Recent technological innovations, especially in digital control systems, have significantly enhanced the precision, speed, and adaptability of these machines. As manufacturers continue to improve the performance of their packaging lines and meet the increasing demand for high-quality products, the advancements in digital control of capping technology provide valuable solutions. These innovations help streamline processes, reduce downtime, and ensure consistent product quality.

A major innovation in modern capping equipment is the introduction of digital control systems. These systems allow operators to precisely manage and monitor the entire capping process in real-time. With intuitive interfaces, operators can adjust key parameters such as torque, speed, and cap placement, ensuring that the machine runs efficiently and consistently. Digital control enables precise capping operations, which is essential for maintaining product integrity, reducing waste, and ensuring a secure seal on every container.

In addition to standard control functions, many advanced capping systems now feature automation that allows for automatic adjustments based on the specific requirements of the product. For instance, when switching between different cap sizes or types, the digital system can quickly adjust machine settings without the need for manual intervention. This not only reduces the time and labor required for adjustments but also minimizes the risk of human error. The ability to rapidly changeover between different products and production batches has become a key feature in industries where versatility and speed are crucial.

Another key area where digital control has made a significant impact is in the precision of the capping process. Traditional capping methods often relied on mechanical adjustments, which could to variations in cap placement or applied pressure. With digital control, manufacturers can now ensure that caps are applied with consistent torque, reducing the risk of leakage, contamination, or product degradation. This is especially critical in industries like pharmaceuticals and food and beverage, where packaging integrity is essential for product safety and shelf life.

Advanced capping machines with digital control also come with built-in diagnostics and performance monitoring features. These systems track operational data and provide real-time feedback on factors like speed, torque levels, and machine performance. If any abnormalities are detected, the system alerts operators to potential issues, enabling quicker interventions and reducing the likelihood of downtime. These diagnostic capabilities enhance the machine's reliability, helping manufacturers avoid costly maintenance and repairs while production uptime.

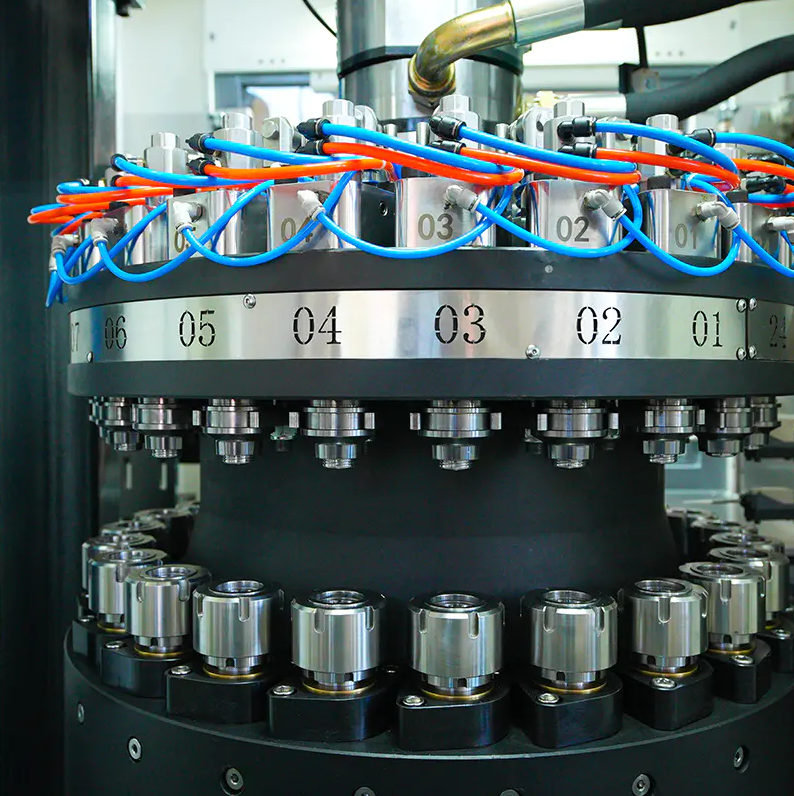

The integration of sensors and cameras into capping equipment further improves control levels. These sensors can detect issues such as misalignment, over-tightened caps, or improper seals, triggering automatic adjustments to ensure that each container is perfectly sealed. With the addition of these sensors, capping systems now operate with greater accuracy, ensuring that even the delicate products are sealed securely and consistently.

The integration of digital control also makes it easier for manufacturers to gather valuable data for continuous improvement. By analyzing production trends, output quality, and operational efficiency, manufacturers can make data-driven decisions to optimize production lines. This data can also be used for predictive maintenance, allowing operators to anticipate when a part may need attention before it leads to machine failure, further improving the overall reliability and efficiency of the capping process.

Another advantage of digital control in capping systems is the ability to customize settings for different production environments. For example, machines can be programmed to adjust speed and torque based on the type of container or material used, ensuring that each cap is applied with the appropriate pressure and precision. This level of customization provides manufacturers with greater flexibility to meet the specific needs of their products and production lines.

As the demand for high-quality, efficient, and sustainable production methods continues to grow, the digital control of Capping Machines plays a key role in advancing packaging technology. The ability to monitor and control every aspect of the capping process in real-time, combined with automation features, is revolutionizing the industry. Manufacturers can now achieve faster production speeds, more accurate capping, and reduced waste, while ensuring that the quality standards are maintained.

By adopting these advanced digital control systems, manufacturers can significantly improve the efficiency and consistency of their production lines. This allows them to remain competitive in a rapidly changing market, where speed, quality, and flexibility are essential. As digital technology continues to evolve, there is even greater potential for innovation in capping systems, promising further improvements in production efficiency, sustainability, and product quality.

Chuangzhen Machinery integrates advanced digital control and automation technologies into its Capping Machines, focusing on precision, reliability, and sustainability. The company provides manufacturers with cutting-edge solutions to enhance production efficiency and meet the growing demands of modern packaging. These innovations allow businesses to deliver high-quality products to the market faster and more efficiently, ensuring a competitive edge in a dynamic industry.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.