In the modern packaging industry, the Cap Compression Machine has become a key technology for balancing production efficiency and material optimization. Unlike traditional injection molding, compression technology is recognized for its ability to reduce plastic waste, improve consistency, and achieve higher production speeds. Engineering innovations in this field continue to transform how manufacturers meet the growing demand for lightweight, sustainable, and cost-effective caps.

Precision Engineering to Minimize Material Usage

One of the main advantages of advanced cap compression technology is its ability to use the exact amount of resin required for each cap. Traditional molding methods often to excess material or trimming, which increases waste and production costs. Modern compression systems integrate precise dosing mechanisms that calculate resin distribution to fractions of a gram. This reduces raw material waste while maintaining consistent cap quality.

Engineers also optimize mold designs by incorporating smaller gate sizes and more efficient resin flow patterns. These improvements allow material to distribute evenly in the cap cavity, eliminating unnecessary excess and further reducing waste during the molding process.

Lightweighting Without Sacrificing Strength

Another engineering innovation focuses on producing lighter caps while maintaining durability and performance. Compression machines now use advanced cooling systems and pressure distribution technologies to create thinner-walled caps. This lightweighting significantly reduces resin usage across millions of units, saving materials and transportation costs.

The challenge is balancing reduced wall thickness with sufficient mechanical strength. Engineers achieve this by designing ribbed cap structures and optimized threads, enhancing grip and sealing performance while using less plastic. This careful balance between form and function demonstrates how precision engineering promotes sustainable manufacturing without compromising user experience.

Faster Cycle Times and Higher Productivity

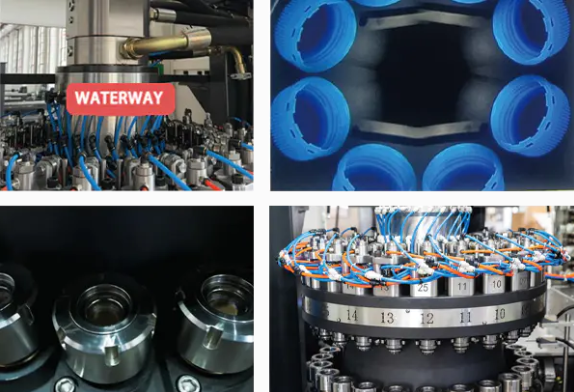

Efficiency improvements are not limited to material savings; they also increase output per machine. Modern compression systems integrate multi-cavity molds and high-speed rotary tables, enabling continuous production cycles. Compared to injection molding, which may be slowed by longer cooling times, compression molding benefits from faster heat transfer and reduced cooling requirements.

For example, new compression systems use water-cooled molds and optimized temperature control units, allowing caps to solidify quickly and move seamlessly to the next production stage. These enhancements reduce cycle time by several seconds per unit, which, at an industrial scale, can result in millions of additional caps annually. Higher productivity translates to lower per-unit energy consumption and increased profitability.

Reducing Defects and Improving Yield

Material waste is often tied not only to resin usage but also to defective products. Misaligned molds, uneven pressure distribution, or temperature inconsistencies can produce caps with poor sealing performance, requiring rework or disposal. Advanced cap compression machines now integrate real-time sensors and automated feedback loops.

These systems monitor cavity pressure, temperature uniformity, and resin flow, correcting deviations during production. By reducing defective units, manufacturers ensure that raw materials directly contribute to usable products, increasing overall yield. Vision inspection systems verify that each cap meets precise dimensional and visual standards before leaving the line, minimizing waste from downstream rejections.

Sustainable Materials and Recycling Integration

Sustainability has become a major driver in packaging engineering, and cap compression machines are central to this shift. Recent innovations allow recycled plastics and bio-based resins to be incorporated without affecting product quality.

Compression technology operates under lower processing pressures than injection molding, reducing material stress and making it easier to process recycled or alternative polymers. This adaptability enables manufacturers to expand the use of sustainable materials while maintaining consistent performance. The process stability also reduces defects caused by contamination, further minimizing waste.

The Future of Material Efficiency in Cap Production

Looking ahead, engineering developments are expected to advance further with the integration of digital twin technology and AI-driven process optimization. By simulating resin flow, mold dynamics, and cycle efficiency virtually, manufacturers can test and refine production processes before implementation. This predictive approach reduces trial-and-error waste and accelerates the adoption of material-efficient designs.

As industries move toward a circular economy, innovations in cap compression machines illustrate how precision engineering, smart automation, and sustainable practices can work together to minimize resource consumption while improving output efficiency. Companies like Chuangzhen Machinery continue to in this field, delivering high-performance cap compression systems that combine flexibility, reliability, and sustainability to meet the evolving needs of modern packaging manufacturers.

中文简体

中文简体 русский

русский Español

Español عربى

عربى