chuangzhen@capping-machine.net

EN

A Capping Machine automates the process of placing and tightening caps on containers. Depending on the design, it can handle different types of closures, including screw caps, snap-on lids, press-on caps, and corks. Its main goal is to ensure consistency, hygiene, and production efficiency while reducing manual labor.

A Capping Machine automates one of the final and delicate steps in the production line — securing caps, lids, or closures onto bottles and containers. What seems like a simple motion carries significant importance for maintaining product integrity. A properly sealed package prevents leakage, contamination, and spoilage, directly impacting shelf life and regulatory compliance. For manufacturers handling liquids, powders, or creams, a stable capping system is not just about speed but about preserving value.

The importance of capping technology is particularly evident in industries that demand strict hygiene and safety standards. In the pharmaceutical sector, for instance, torque-controlled capping ensures child-resistant closures and tamper-evident seals, which are required by international regulations. In food and beverage production, uniform sealing minimizes exposure to air and microorganisms, maintaining freshness and taste from factory to consumer. Without dependable capping systems, even minor inconsistencies could to product recalls, economic losses, and reputational damage.

As the packaging sector moves toward automation and smart manufacturing, the capping process has undergone major technical upgrades. Modern machines integrate servo-driven torque control, intelligent cap feeders, and vision inspection systems that detect improper seals in real time. This integration of sensors and data analytics supports Industry 4.0 principles, allowing operators to monitor torque accuracy, reject defective caps automatically, and adjust parameters digitally without halting production. The result is enhanced efficiency, reduced waste, and higher overall equipment effectiveness.

Another driving factor in the popularity of capping equipment is sustainability. The transition to lightweight caps, recycled materials, and energy-efficient systems has encouraged manufacturers to adopt cap compression molding machines and other precision-based technologies that minimize raw material use. Unlike traditional injection molding, compression molding reduces plastic waste and improves cap uniformity, contributing to greener production. When combined with advanced capping lines, these innovations support both environmental goals and economic competitiveness.

From an operational standpoint, Capping Machines provide flexibility across different container shapes and materials. Adjustable torque heads and quick-change components allow manufacturers to switch between product lines with minimal downtime. This adaptability has become essential as brands diversify packaging designs to meet evolving consumer preferences and sustainability demands. Whether producing small pharmaceutical vials or large detergent bottles, a well-configured capping system ensures consistency and performance across varied product formats.

Moreover, the human factor in packaging has shifted from manual handling to digital supervision. Modern capping systems often feature touchscreen interfaces, programmable settings, and safety interlocks, simplifying training and reducing physical strain for operators. These ergonomic improvements align with global workplace safety standards while enabling production teams to focus on process optimization rather than repetitive manual tasks.

In global trade, packaging reliability can define the success of a product line. International markets expect uniform quality regardless of location, and that begins with consistent sealing standards. The ability of capping machines to deliver repeatable results under different production conditions makes them indispensable to multinational brands seeking both efficiency and compliance.

As packaging continues to evolve with trends like smart labeling, eco-friendly materials, and automation-driven customization, the role of the Capping Machine becomes even more critical. It connects sustainability, technology, and safety into one process that supports modern industry demands while maintaining flexibility for future innovations.

At its core, a capping system functions by aligning, placing, and tightening caps onto bottles or containers in a controlled and repeatable manner. This ensures that each container is sealed properly, protecting its contents from leakage, contamination, or external impact during storage and transportation. The process begins with the feeding system, followed by cap orientation, application, torque control, and quality verification.

The operation typically starts with a cap feeder — a mechanical or vibratory device that arranges loose caps in a uniform direction. This ensures that every cap enters the capping station in the correct orientation. The feeder works together with a cap chute or pick-and-place mechanism that transfers the caps smoothly onto passing containers on the conveyor. The synchronization between the bottle infeed and the cap delivery system is essential to prevent misplacement and ensure a continuous production rhythm.

Once the cap is positioned on the container, the capping head or torque mechanism takes over. Depending on the machine design, the head can apply pressure or rotational torque to secure the closure. There are several main types of capping systems — screw cappers, snap cappers, and press-on cappers — each tailored to different packaging materials and closure styles. Screw cappers, for example, use spinning chuck heads to apply precise torque levels, ensuring the cap is tight enough to seal but not so tight as to damage threads or deform the bottle.

In high-speed automated systems, servo motors and electronic torque sensors replace traditional mechanical adjustments. This enables accurate and consistent torque application, which is critical for maintaining product uniformity and compliance with packaging standards. The machine can be programmed to handle various cap sizes and torque settings, allowing manufacturers to switch between product lines with minimal manual intervention.

A key part of the process is torque control, which determines how securely the cap is fastened. Insufficient torque can to leaks or loose closures, while excessive torque can cause damage or make it difficult for consumers to open the product. Modern capping systems use servo-controlled torque heads that can be adjusted digitally, ensuring stable results even when handling containers of different shapes or materials.

After capping, integrated inspection systems verify closure integrity. Vision cameras and torque sensors detect improperly sealed or misaligned caps and automatically reject faulty products. This level of quality assurance is particularly important in industries such as pharmaceuticals, beverages, and cosmetics, where packaging errors can affect safety and brand reliability.

Many advanced capping machines are part of a larger automated packaging line, connected to bottle fillers, labelers, and conveyors through programmable logic controllers (PLCs). These control systems manage the timing and coordination of each operation, improving throughput and reducing downtime. In addition, smart interfaces allow operators to monitor real-time data, adjust settings, and receive maintenance alerts directly from the touchscreen panel.

Another significant aspect of how a Capping Machine works is its mechanical design for flexibility and hygiene. Machines are typically constructed from stainless steel to meet food and pharmaceutical standards, with tool-free changeover parts and easy-to-clean surfaces. Pneumatic or magnetic clutch systems help maintain smooth and controlled motion, reducing wear and extending the machine’s lifespan.

In applications where caps are made by cap compression molding, integration between molding and capping processes further enhances production efficiency. Compression-molded caps are known for their uniformity and material stability, providing an ideal match for automated capping systems. This combination supports both precision and sustainability by minimizing material waste and improving product performance.

The working principle of a Capping Machine reflects the evolution of manufacturing itself — from mechanical control to intelligent automation. Every step, from cap feeding to torque application and inspection, is carefully engineered to ensure a consistent, high-quality seal that upholds both product safety and brand reputation.

The process begins with the cap feeder or sorter, a mechanical or vibratory unit responsible for orienting and supplying caps in a continuous, organized flow. Caps typically enter the feeder in a random orientation, and through controlled vibration or mechanical sorting, they are aligned uniformly before entering the chute. This ensures that each cap arrives at the capping station in the correct position, allowing uninterrupted operation and reducing the risk of misfeeds or production delays. The feeder plays a critical role in maintaining line efficiency and ensuring each container receives the right closure without manual handling.

Once the caps are properly aligned, they are guided toward the capping head or chuck — the main component that performs the sealing action. The capping head can apply downward pressure or rotational torque, depending on the type of closure. For screw caps, the chuck head spins to tighten the cap securely onto the container threads. Snap or press-fit closures, by contrast, rely on pressure to fasten the lid firmly in place. The design of the capping head determines how torque and force are applied, balancing tightness and safety to avoid product leakage while ensuring easy opening for end users.

To achieve consistent and precise results, the torque control system comes into play. This mechanism manages the amount of torque applied to each closure, ensuring uniform sealing across all containers. Insufficient torque can result in loose caps or leakage, while excessive torque can cause thread damage or deform the closure. Modern torque systems often include adjustable clutch mechanisms or electronic sensors that monitor the torque in real time. This allows operators to fine-tune performance, improve repeatability, and maintain stable quality standards throughout extended production runs.

Supporting all these components is the conveyor system, which continuously moves bottles or containers through each stage of the capping process. The conveyor must maintain accurate positioning and timing to synchronize with the feeder and capping head. In fully automated lines, sensors detect bottle spacing, ensuring that each container stops precisely under the capping head. The smooth movement of the conveyor minimizes vibration and prevents spills or misalignment, both of which are essential for high-speed and high-volume operations.

Additional elements often enhance the performance of these core components. Bottle stabilizers and grippers hold containers firmly in place during capping, preventing rotation or tipping. Height adjustment mechanisms allow the capping head to adapt to containers of different sizes. Integrated control panels and programmable logic controllers (PLCs) coordinate the entire process, managing synchronization between feeding, capping, and conveying systems. These automation features not only improve productivity but also reduce the need for manual supervision and repetitive adjustments.

The combined function of these components ensures that a Capping Machine delivers reliable, repeatable sealing performance. Each part — from the feeder that organizes caps to the torque system that controls sealing force — contributes to operational stability and product quality. By integrating mechanical precision with intelligent control, capping systems enable manufacturers to maintain hygiene, safety, and efficiency in diverse packaging applications ranging from beverages to pharmaceuticals.

Working Principle:

The automatic capping machine manages the entire capping process without manual intervention. Caps are fed automatically from a hopper or sorting system, positioned precisely over containers on a conveyor, and sealed using controlled torque. The continuous operation ensures each container receives an accurate and reliable closure.

Applications:

Advantages:

Working Principle:

In a semi-automatic capping machine, operators manually place caps onto containers, while the machine automatically tightens or seals the caps with precise torque control. This setup allows flexibility while maintaining consistent closure quality.

Applications:

Advantages:

Working Principle:

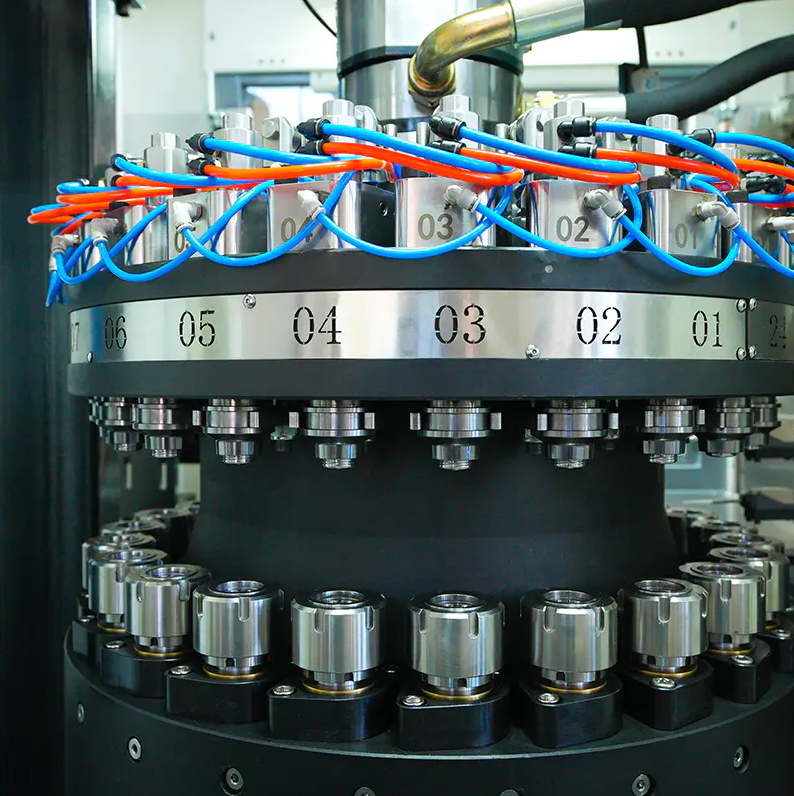

Rotary capping machines use multiple rotating heads that continuously apply torque as bottles move through the system on a rotating platform. Each head operates independently, enabling high-speed operation without sacrificing accuracy.

Applications:

Advantages:

Working Principle:

Chuck capping machines utilize a mechanical chuck to grip and twist caps securely onto containers. Controlled torque ensures a tight and consistent seal, particularly suitable for screw-type caps.

Applications:

Advantages:

Working Principle:

Snap capping machines apply a calibrated downward force to press caps onto container necks. Unlike rotational systems, this method secures push-on or snap-fit closures efficiently.

Applications:

Advantages:

Working Principle:

Hybrid and custom systems combine features of rotary and chuck machines, often incorporating smart sensors, torque monitoring, and adaptive feedback to enhance precision and flexibility.

Applications:

Advantages:

|

Type of Capping Machine |

Working Principle |

Applications |

Advantages |

|

Automatic Capping Machine |

Manages the entire capping process automatically. Caps are fed from a hopper or sorting system, positioned precisely, and sealed using controlled torque. Continuous operation ensures accurate and reliable closures. |

High-volume beverage lines; Pharmaceuticals; Personal care products |

Reduces labor and human error; Ensures consistent, reliable sealing |

|

Semi-Automatic Capping Machine |

Operators manually place caps while the machine automatically tightens or seals them with precise torque control. Provides flexibility while maintaining closure quality. |

Small-batch beverages; Artisanal food products; Specialty cosmetics and health products |

Cost-effective and flexible; Suitable for transitioning from manual to automated; Precise torque control for consistent closure |

|

Rotary Capping Machine |

Uses multiple rotating heads that continuously apply torque as bottles move on a rotating platform. Each head operates independently for high-speed, accurate operation. |

Beverage, dairy, and cosmetic production lines |

High-speed operation with uniform sealing; Smooth workflow with minimal vibration; Ensures product integrity for delicate containers |

|

Chuck Capping Machine |

Uses a mechanical chuck to grip and twist caps onto containers. Controlled torque ensures tight and consistent seal, suitable for screw-type caps. |

Pharmaceuticals; Nutraceuticals; Premium beverages |

High repeatability and strong grip; Accommodates various cap sizes and materials; Handles delicate or irregular caps without damage |

|

Snap Capping Machine |

Applies calibrated downward force to press caps onto container necks. Efficient for push-on or snap-fit closures without rotation. |

Dairy; Juice; Cosmetics; Lightweight or flexible packaging |

Fast changeovers; Simple operation; Reduces risk of damage; Supports hygienic packaging |

|

Hybrid and Custom Capping Machines |

Combines features of rotary and chuck machines, often with smart sensors, torque monitoring, and adaptive feedback for enhanced precision and flexibility. |

Food and beverage; Personal care; Pharmaceuticals; Household chemicals |

Enhanced precision and adaptability; Handles new packaging materials and designs; Easily integrates into complex production lines |

One of the primary benefits of using a capping machine is its efficiency. By automating the sealing process, production lines can achieve continuous operation with minimal downtime. The system handles repetitive tasks at a consistent pace, eliminating the variability and fatigue that come with manual labor. For manufacturers dealing with high volumes, this consistency ensures that each product is sealed securely, allowing faster turnaround and greater throughput without compromising precision. The reliable operation of a capping system enhances workflow continuity and supports large-scale production targets.

Another essential advantage is quality assurance. A capping machine ensures that every closure is applied with uniform torque and pressure, reducing the likelihood of leaks, contamination, or cap misalignment. Consistent torque application is especially important in industries such as pharmaceuticals and beverages, where packaging integrity directly affects product safety and shelf life. Automated control mechanisms and precise alignment features help maintain sealing uniformity across thousands of units, contributing to dependable quality and consumer trust.

The reduction of labor costs is another key factor driving the adoption of capping machines. Automating the capping process minimizes the need for manual handling, freeing operators to focus on supervision, inspection, or other skilled tasks. This shift not only improves workplace efficiency but also reduces the risk of repetitive strain injuries associated with manual capping. By lowering reliance on manual intervention, manufacturers can maintain steady production even with limited staffing resources, to long-term operational savings.

Versatility is also a defining characteristic of modern capping equipment. A single system can often handle various container shapes, cap types, and closure mechanisms, from screw-on lids to snap-fit designs. This adaptability allows producers to streamline their packaging operations without the need for multiple machines. Whether dealing with small cosmetic jars or large beverage bottles, adjustable components and modular setups make it easier to accommodate changing product lines or packaging trends. Such flexibility supports faster changeovers and helps manufacturers stay responsive to market demands.

Equally important are hygiene and safety, particularly in industries where contamination control is essential. Automated capping systems minimize human contact with open containers, reducing the chance of introducing impurities during the packaging process. This is critical in food, beverage, and pharmaceutical production, where product safety regulations are stringent. Moreover, the enclosed and controlled operation of these machines ensures that caps are applied cleanly, maintaining both hygiene and product integrity. The ability to achieve secure closures also prevents accidental spillage or tampering during transportation and storage.

The overall impact of a capping machine extends to operational reliability and brand perception. A well-sealed product not only meets compliance standards but also reflects manufacturing excellence. Customers associate secure packaging with professionalism and trustworthiness, making precise sealing a subtle yet powerful marketing asset. In highly competitive markets, investing in dependable capping technology allows manufacturers to safeguard both their production efficiency and brand reputation.

A capping machine is an automated device designed to accurately apply caps,It is widely used across multiple industries for efficient and consistent packaging.

Food and Beverage: Bottled drinks, sauces, condiments, and other consumables require airtight seals to maintain freshness and prevent leaks.

Pharmaceuticals: Medications, syrups, and supplements must be sealed with precision to ensure sterility and compliance with safety standards.

Cosmetics and Personal Care: Products like lotions, shampoos, and creams rely on dependable capping for spill prevention and user convenience.

Chemical and Industrial Products: Containers for cleaners, oils, and other chemicals demand robust seals to avoid hazardous spills.

Household Products: Everyday items such as detergents, disinfectants, and air fresheners also utilize capping machines for safe, efficient packaging.

In the food and beverage industry, capping machines play a vital role in securing bottles and containers to maintain product freshness and safety. They are used for sealing bottled beverages such as water, juice, and carbonated drinks, as well as dairy products including milk bottles and yogurt cups. Condiments and sauces, from cooking oils to soy sauce and vinegar, also rely on precise capping to preserve flavor and prevent leaks. In addition, canned and jarred foods benefit from reliable closures to protect contents during transportation and storage.

The pharmaceutical industry depends heavily on capping machines to ensure the sterility and integrity of medical products. Pill bottles, vials, and other medication containers require secure closures to prevent contamination and maintain efficacy. Nutraceuticals and dietary supplements also need consistent sealing for capsules, tablets, and liquid formulations. Capping machines are also essential for medical liquids, including injectables and disinfectants, providing secure and reliable closure under stringent safety standards.

Within the cosmetics and personal care sector, capping machines contribute to both product performance and aesthetic appeal. Skincare products such as creams, lotions, and serums require secure sealing to maintain their quality over time. Perfume and fragrance bottles demand precision to protect both scent and presentation, while hygiene products such as shampoos, body washes, and liquid soaps benefit from automated screw-capping for consistent application and tamper resistance.

In the chemical industry, precise and secure capping is critical to prevent spills, contamination, and safety hazards. Paints and coatings, whether for industrial or household use, need reliable sealing to maintain usability and prevent drying. Cleaning agents, including detergents and bleach, are sealed efficiently to ensure safe handling, while lubricants and oils used in automotive and industrial applications require consistent closure to avoid leakage and degradation.

Capping machines also find application in other specialized sectors, where safety and reliability are paramount. Agrochemicals, such as fertilizers and pesticides, demand secure closures to prevent accidental exposure and maintain potency. Laboratory supplies, including reagent bottles and chemical storage containers, rely on precise capping to preserve contents and maintain laboratory safety. Automotive products such as antifreeze, windshield washer fluids, and other car care liquids also benefit from automated sealing to prevent leaks and maintain product quality.

Production Volume and Speed are key factors when choosing a capping machine. High-volume operations often require fully automated systems that can handle continuous production without compromising consistency. For smaller or variable production runs, semi-automatic machines may provide flexibility while maintaining reliable sealing performance. Matching the machine's capacity to the expected output ensures smooth workflow and reduces bottlenecks.

Cap Types and Materials play a significant role in machine selection. Machines must accommodate a variety of closures, including screw caps, snap-on caps, child-resistant designs, and flexible or lightweight materials. Different cap compositions may respond differently to applied torque, requiring machines with adjustable mechanisms to prevent over-tightening, deformation, or leakage.

Container Shapes and Sizes also influence the choice. Bottles and jars can be round, square, or irregularly shaped, and the capping system must securely engage the container to achieve consistent sealing. Some machines offer adaptable platforms or grippers to handle multiple container types without extensive adjustments, which enhances versatility and efficiency.

Torque Control and Consistency are critical for ensuring that every closure is properly sealed. Machines equipped with precise torque regulation prevent damage to caps and containers while maintaining uniformity across production batches. This capability is especially important in industries where product integrity and safety are paramount.

Automation Level and Labor Costs should be considered in line with production requirements. Fully automatic machines reduce manual handling and labor expenses while maintaining a high throughput. Semi-automatic systems allow for human intervention where needed and are suitable for variable or small-scale operations, providing a balance between efficiency and flexibility.

Maintenance and Durability are essential for long-term operational reliability. Machines constructed with high-quality materials and easy-to-service components minimize downtime and ensure consistent performance. Regular maintenance routines further extend machine lifespan and safeguard production continuity.

Compliance and Hygiene requirements differ by industry. Food, pharmaceutical, and personal care packaging demand machines that adhere to strict safety and hygiene standards. Machines should support clean environments and prevent contamination while providing secure closures that meet regulatory expectations.

Flexibility for Future Needs ensures that the machine remains relevant as production evolves. Compatibility with emerging cap designs, materials, and packaging trends allows manufacturers to adapt without investing in entirely new equipment. This forward-looking approach maximizes return on investment and operational resilience.

Food & Beverage: High-speed automatic or rotary machines ensure rapid, consistent sealing for beverages, condiments, and dairy products.

Pharmaceuticals & Nutraceuticals: Chuck capping machines offer precise torque control, critical for sterility and secure closures.

Cosmetics & Personal Care: Semi-automatic or rotary systems handle small batches efficiently while accommodating unique bottle designs.

Chemicals & Industrial Products: Snap or chuck machines provide robust and reliable closures for safety-critical containers.

With evolving packaging demands, technological innovations have transformed how these machines operate, enabling higher precision, faster production, and greater adaptability across multiple industries.

Modern capping machines leverage advanced automation systems that integrate seamlessly with production lines. Fully automated systems handle the entire process from cap feeding and positioning to torque application and sealing, significantly reducing the need for manual intervention. Semi-automatic options offer flexibility for smaller batches or products requiring frequent changeovers while still benefiting from automated torque control and consistent sealing. These automation improvements optimize production flow, reduce human error, and maintain consistent output.

Precision torque and sealing control have also evolved, allowing machines to adjust the applied force according to cap types and materials. Adaptive torque systems ensure closures remain secure without damaging delicate or flexible caps. This technology reduces leakage risk and preserves product integrity, which is particularly important for food, beverage, pharmaceutical, and personal care items. By monitoring and regulating torque in real time, machines maintain uniform quality across diverse production lines.

Cap feeding and handling systems have undergone significant innovation as well. Intelligent sorting mechanisms automatically arrange and deliver caps, including irregular, lightweight, or flexible types, minimizing downtime and human intervention. These improvements contribute to faster production speeds and fewer errors, ensuring that even challenging closures are handled efficiently.

Rotary and multi-head capping systems provide additional benefits in high-volume operations. Multiple rotating heads operate simultaneously to maintain consistent torque while increasing throughput. These systems are ideal for industries where speed and product integrity are critical, such as beverages, cosmetics, and pharmaceuticals. The smooth operation of rotary machines also reduces vibration and mechanical stress on caps, improving overall efficiency.

Integration of sensors and data analytics has further advanced capping technology. Sensors monitor torque, alignment, and sealing quality, providing feedback for real-time adjustments. Data from these systems enables manufacturers to track performance trends, identify potential issues, and optimize operations, ensuring consistent output while supporting predictive maintenance strategies.

Energy efficiency and sustainability have become integral considerations in capping machine design. Innovations such as energy-efficient drives, lightweight mechanical components, and reduced mechanical strain contribute to lower operational costs and environmental impact. Eco-friendly lubricants and processes also minimize waste while extending equipment lifespan.

Flexibility and modularity are increasingly important for meeting diverse packaging requirements. Adjustable capping heads, modular platforms, and quick-change systems allow manufacturers to switch between different container shapes, sizes, and cap types efficiently. This adaptability ensures that machines remain relevant even as packaging trends evolve, supporting emerging materials and new closure designs.

Safety and hygiene enhancements are crucial, especially in food, pharmaceutical, and cosmetic applications. Modern machines incorporate touchless or low-contact sealing mechanisms to reduce contamination risk. Ergonomic designs improve operator safety, while integrated cleaning and sterilization features help maintain sanitary conditions on the production line.

Technological innovation in capping machines continues to align with industry demands, emphasizing precision, adaptability, and connectivity to meet diverse production requirements while supporting emerging packaging trends.Chuangzhen Machinery specializes in providing versatile, reliable capping machines that combine precision engineering with energy-efficient automation, enabling businesses to optimize their production lines, improve operational consistency, and adapt to emerging packaging trends without compromising performance.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.