chuangzhen@capping-machine.net

EN

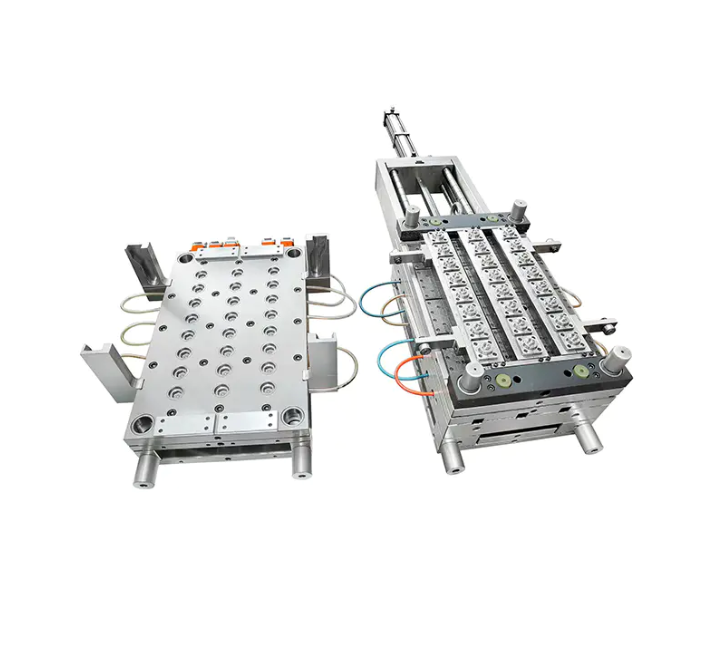

In modern packaging manufacturing, efficiency and sustainability are key considerations. A Plastic Cap Compression Molding Machine demonstrates how continuous compression molding can achieve both high productivity and energy efficiency. This process involves feeding plastic material into a plasticizing unit, cutting it into pellets, and precisely placing them into mold cavities for compression into finished caps. By operating at optimized lower extrusion temperatures, these machines reduce cooling times, save energy, and ensure consistent product quality, providing manufacturers with an effective solution for large-scale production.

The continuous compression molding process begins with the plasticizing unit, where raw plastic materials are heated and softened for precise molding. Unlike traditional injection molding, which requires higher melt temperatures, modern compression systems are designed to operate efficiently at lower temperatures. Once the plastic reaches the desired consistency, it is cut into uniform pellets and transferred under controlled pressure into mold cavities. The molded caps are then cooled and ejected, ready for packaging.

This continuous production method ensures a stable workflow, minimizes variations in cycle time, and maintains high quality across large batches. Reduced thermal demands also lower wear on mechanical components and downstream cooling systems, extending equipment longevity.

A key advantage of modern cap compression machines is energy efficiency. Operating at lower extrusion temperatures reduces the heat required to soften plastic materials, directly lowering electricity consumption. Reduced thermal input also minimizes stress on molds and heating elements, decreasing maintenance needs and extending the lifespan of critical components.

Lower melt temperatures shorten the cooling phase of each cycle, allowing the machine to produce a higher number of caps per hour without compromising quality. Even slight reductions in cycle time can result in significant improvements in output and operational efficiency for high-volume production environments.

Cooling is a critical step in the molding process. In conventional systems, long cooling times can create bottlenecks and limit overall production speed. Continuous compression molding at lower processing temperatures addresses this challenge effectively.

By reducing the time needed for caps to reach a stable form, production lines can operate at higher speeds while maintaining consistent dimensions and mechanical properties. Faster cooling cycles also reduce energy consumption from auxiliary equipment such as chillers and cooling tunnels, creating a more streamlined and resource-efficient production workflow.

Accurate material handling is essential for maintaining consistent cap quality. Modern compression molding machines incorporate advanced feeding mechanisms that precisely deliver plastic pellets into each mold cavity. Controlled timing and optimized molding pressure ensure uniform caps with minimal waste.

Lower processing temperatures help preserve the integrity of sensitive polymers, preventing discoloration or structural defects. This allows manufacturers to produce high-quality caps efficiently without increasing energy consumption.

The evolution of cap compression molding aligns with Industry 4.0 principles. Machines can now be equipped with sensors and control systems to monitor temperature, pressure, and output in real time. Data collected during the molding process supports predictive maintenance, reducing unexpected downtime and improving reliability.

Automated monitoring can dynamically adjust heating and compression parameters to optimize energy use. This ensures the machine operates only at the required power levels, avoiding unnecessary energy consumption and supporting sustainable manufacturing goals.

Energy-efficient continuous compression molding impacts both environmental and economic performance. Reduced electricity usage lowers operating costs and carbon emissions. Shorter cooling times reduce reliance on auxiliary cooling systems, further decreasing energy requirements.

Lower processing temperatures also minimize material degradation, reducing scrap rates and plastic waste. Manufacturers can therefore deliver high-quality caps while promoting responsible resource management.

Modern cap compression systems handle diverse thermoplastic materials with varying flow and thermal properties. Lower extrusion temperatures allow delicate polymers to be molded without compromising structural integrity. Combined with precise pressure and timing control, this enables the production of caps with consistent wall thickness and accurate threads.

Material optimization further supports energy efficiency. By selecting polymers suitable for low-temperature processing, manufacturers can reduce energy use while maintaining mechanical performance, meeting diverse market needs and sustainable production standards.

High-efficiency cap compression machines improve productivity by combining speed, precision, and energy savings. Faster cooling cycles, lower energy consumption, and reduced wear allow production lines to operate continuously with fewer interruptions.

The continuous process ensures stable output for high-volume operations, while intelligent monitoring minimizes downtime. For manufacturers producing beverage caps, food closures, or other packaging components, this results in clear benefits in cost efficiency, product quality, and energy management.

As global demand for packaged products grows, manufacturers seek solutions that balance operational efficiency and environmental responsibility. Continuous compression molding with optimized temperature profiles and energy-saving features provides a pathway to future-ready production. Taizhou Chuangzhen Machinery specializes in designing and manufacturing advanced plastic cap compression molding machines, integrating lower-temperature operation, real-time monitoring, and high-precision material handling. By adopting Chuangzhen’s solutions, packaging manufacturers can balance productivity, quality, and sustainability, achieving consistent performance while preparing for future innovation in packaging technology.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.