chuangzhen@capping-machine.net

EN

As manufacturing continues to evolve toward greater automation and connectivity, the Capping Machine has become a crucial part of modern industrial intelligence. In today’s high-speed production lines, this equipment is no longer just a mechanical tool for sealing bottles—it has transformed into an intelligent node within the Internet of Things (IoT) ecosystem. Through the integration of data-driven control, sensor technology, and advanced analytics, modern capping systems are setting new benchmarks for precision, sustainability, and operational efficiency in the global packaging industry.

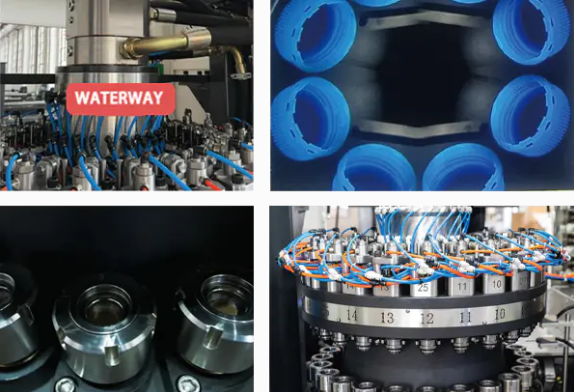

In the era of Industry 4.0, the capping process is transitioning from manual or semi-automatic operation to fully integrated smart systems. IoT-enabled capping machines can collect and transmit real-time data from multiple sensors, including torque sensors, pressure gauges, and vibration monitors. This continuous flow of information enables manufacturers to track performance, detect irregularities early, and optimize machine parameters for consistent output.

This level of connectivity means capping machines are no longer isolated units—they can integrate seamlessly with other equipment on the production line, such as filling and labeling machines. Through synchronized communication protocols, all systems work together, reducing downtime and ensuring each product passes through every production stage with minimal waste and high precision.

Sensors are the cornerstone of intelligent capping technology. They gather essential data from every production cycle and transform it into actionable insights. Optical sensors ensure the cap is correctly positioned, torque sensors maintain stable sealing pressure, and vibration sensors detect early signs of mechanical imbalance. Advanced sensor arrays can identify microscopic variations in torque or alignment, which may indicate component wear or calibration drift. This proactive feedback mechanism allows operators to intervene before defects occur, preserving product integrity and reducing rework.

One of the transformative applications of IoT in capping technology is predictive maintenance. Traditional maintenance relies on fixed intervals, which can cause unnecessary downtime or unexpected failures. In contrast, smart capping systems continuously monitor mechanical and electrical components through embedded sensors.

By analyzing vibration patterns, torque fluctuations, and energy consumption trends, the system can forecast potential problems before they escalate. This predictive approach extends equipment lifespan, reduces repair expenses, and prevents interruptions in the packaging process. For manufacturers focused on lean production, this feature helps maintain stable product quality while uptime.

As industries move toward sustainable practices, modern capping machines are increasingly designed with energy efficiency in mind. IoT-based monitoring enables precise control over motor speed, pneumatic systems, and servo mechanisms, optimizing power consumption without sacrificing performance. Real-time analytics can identify energy-intensive stages within the capping cycle, allowing operators to make informed adjustments that improve efficiency.

Advanced control systems also ensure each cap is sealed with appropriate torque and pressure, minimizing material waste caused by over-tightening or improper sealing. This approach conserves resources and reduces the carbon footprint of packaging operations, supporting global sustainability goals.

The evolution of capping technology reflects the growing demand for faster and more flexible packaging lines. Traditional production systems often struggled with bottlenecks, inconsistent processes, and human error. However, today’s capping systems can handle a wide variety of container types and sizes, automatically adjusting through servo-driven components and digital interfaces. Operating at speeds of several thousand units per hour, these machines enable manufacturers to meet increasing market demand while maintaining precision and quality.

True efficiency in a packaging line lies in coordination among its components. Modern capping machines are no longer standalone devices—they are integral elements within synchronized production systems. When integrated into automated lines, the capping machine communicates seamlessly with fillers, sorters, and labelers using industrial communication protocols such as OPC-UA and MQTT. This coordination ensures smooth operation and prevents bottlenecks. From filling and capping to labeling, the entire packaging process runs with remarkable continuity, minimizing idle time and improving overall equipment efficiency (OEE).

The next frontier in intelligent capping technology lies in artificial intelligence (AI) and data analytics. Sensors across the production line continuously capture data such as torque, cycle time, temperature, vibration, and output. This information is processed through cloud-based analytics platforms, providing operators with actionable insights. By monitoring real-time data, production teams can identify inefficiencies, predict maintenance needs, and fine-tune operational parameters for performance.

By collecting and analyzing extensive operational data, AI-powered systems can recommend process improvements, adjust capping parameters, and even forecast production trends. This enables manufacturers to improve consistency, reduce energy usage, and enhance productivity across multiple facilities.

In addition, digital twins—virtual models of physical capping systems—allow engineers to simulate performance, test new materials, and explore process modifications in a risk-free environment. The fusion of AI and IoT creates a pathway toward self-optimizing and adaptive manufacturing systems.

As the packaging industry advances toward intelligent automation, capping machines are positioned to play an increasingly central role. The convergence of IoT, predictive maintenance, and real-time analytics has built a strong foundation for future-ready production lines. Combining speed, precision, and environmental responsibility, these systems empower manufacturers to stay competitive in a data-driven global market.

Taizhou Chuangzhen Machinery is this transformation in capping technology. Their innovative machines are not only capable of sealing bottles efficiently but also of communicating, learning, and adapting. By embedding sustainable design principles and intelligent engineering, Chuangzhen provides manufacturers with reliable solutions that balance performance with environmental responsibility—driving the next evolution of smart packaging manufacturing.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.