chuangzhen@capping-machine.net

EN

In modern packaging manufacturing, the Cap Compression Molding Machine plays a vital role in producing plastic caps for beverages, cosmetics, and pharmaceuticals. As industries strive to enhance productivity and maintain consistent quality, the debate between single-cavity and multi-cavity systems has become increasingly prominent. Each configuration offers distinct advantages and trade-offs in cycle time, mold investment, maintenance, and operational control. Therefore, the choice depends on specific production needs rather than a one-size-fits-all approach.

Single-cavity cap compression molding machines are typically suited for precision or small-scale production. These systems contain only one molding cavity, allowing manufacturers to maintain precise control over every stage of the compression process—from resin feeding and temperature regulation to compression force and cooling. Since each cycle produces a single cap, operators can fine-tune parameters without affecting other cavities. This setup reduces the risk of defects and allows for quick process adjustments during product development. It is particularly valuable for producing specialty caps, limited-edition packaging, or new prototype designs that require consistent quality assurance during the testing phase.

Single-cavity systems also provide notable benefits in terms of setup and maintenance. Mold changes are simpler, downtime is shorter, and spare part management is easier. The compact design of the mold makes inspection and cleaning more convenient, reducing contamination risks in sensitive applications such as pharmaceutical packaging. In addition, because temperature gradients and pressure distribution remain uniform throughout the process, single-cavity machines achieve dimensional stability. However, their main limitation lies in production speed—output is significantly lower compared to multi-cavity systems, posing a challenge for manufacturers operating in high-demand environments.

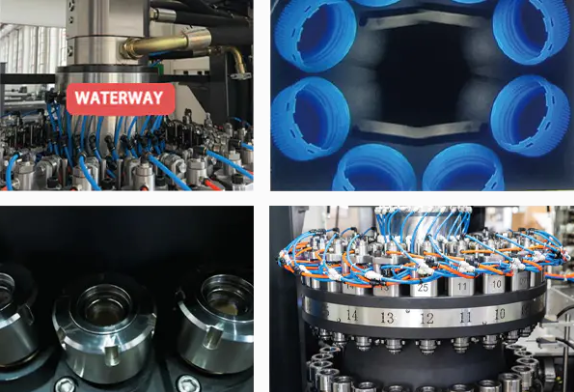

In contrast, multi-cavity cap compression molding machines are designed to maximize efficiency and output. These systems feature multiple cavities, allowing several caps to be molded simultaneously in each cycle, making them ideal for large-scale production facilities. Beverage manufacturers, for instance, rely on multi-cavity configurations to meet the continuous demand for millions of caps per day while maintaining high consistency between batches. Each cavity operates within a balanced system that evenly distributes material and precisely regulates cooling cycles. This scalability results in lower per-cap costs, reduced labor input, and machine utilization during long production runs.

Technological innovations have further improved the performance of multi-cavity systems by addressing previous challenges related to uneven material flow or thermal imbalance. Advanced computer control modules now monitor cavity temperature, pressure levels, and compression timing in real time. These intelligent systems ensure that each cap meets exact specifications even during high-speed operations. Furthermore, modular mold designs allow for quick cavity replacement without dismantling the entire mold, minimizing downtime and improving flexibility when switching between different cap types or sizes.

Despite their efficiency advantages, multi-cavity machines require higher initial investment and meticulous calibration. Each cavity must be precisely machined and maintained to identical tolerances to prevent product variation. Minor deviations in cavity wear or temperature distribution can to inconsistencies in wall thickness or sealing performance. Therefore, regular maintenance and precise monitoring are essential for sustained performance. Manufacturers often integrate automated inspection systems, using optical sensors or AI cameras to detect abnormalities early in the production line.

Material flow behavior also influences machine configuration decisions. In single-cavity machines, the polymer melt flows through a straight channel, minimizing shear stress and reducing material degradation risks. In contrast, multi-cavity systems rely on a more complex flow network where even slight viscosity changes can affect cavity filling balance. Engineers address this challenge through optimized channel design, pressure feedback loops, and dynamic temperature control. These improvements ensure consistent compression performance, especially when processing advanced resin materials such as high-density polyethylene (HDPE) or bio-based alternatives increasingly used in sustainable packaging applications.

From an operational flexibility perspective, single-cavity machines remain advantageous for manufacturers that require frequent mold changes or customization. They enable quick transitions between designs without prolonged production interruptions. Multi-cavity systems, on the other hand, are ideal for standardized, high-volume production where continuity is prioritized over adaptability. For example, a beverage cap producer manufacturing uniform 28mm carbonated drink caps benefits from the high efficiency of multi-cavity designs, while a cosmetics company developing uniquely shaped caps may find the precision and adaptability of single-cavity systems more beneficial.

Environmental and energy efficiency considerations are also reshaping machine selection. While multi-cavity systems generally consume more total energy due to their scale, they achieve higher productivity per energy unit, reducing energy use per cap. Meanwhile, single-cavity machines offer more precise control of heating and cooling cycles, minimizing waste during short production runs. Manufacturers increasingly integrate energy recovery systems, servo-driven controls, and low-friction materials to optimize power utilization and extend component life, aligning production practices with global sustainability goals.

As a pioneer in compression molding technology, Taizhou Chuangzhen Machinery continues to refine both single-cavity and multi-cavity cap compression molding systems. By combining precision engineering, intelligent control, and modular mold design, the company delivers flexible solutions tailored to a wide range of cap applications, ensuring efficiency, reliability, and innovation in every production line.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.