chuangzhen@capping-machine.net

EN

The Cap Compression Machine has become an indispensable tool in modern packaging manufacturing, particularly for high-volume production of plastic bottle caps used in beverages, pharmaceuticals, and personal care products. Among the evolving innovations, multi-cavity systems have emerged as transformative technology, enabling manufacturers to increase production efficiency while maintaining consistent quality across each cycle. These machines integrate advanced mechanical design and automation technologies, meeting the growing market demands for both efficiency and precision.

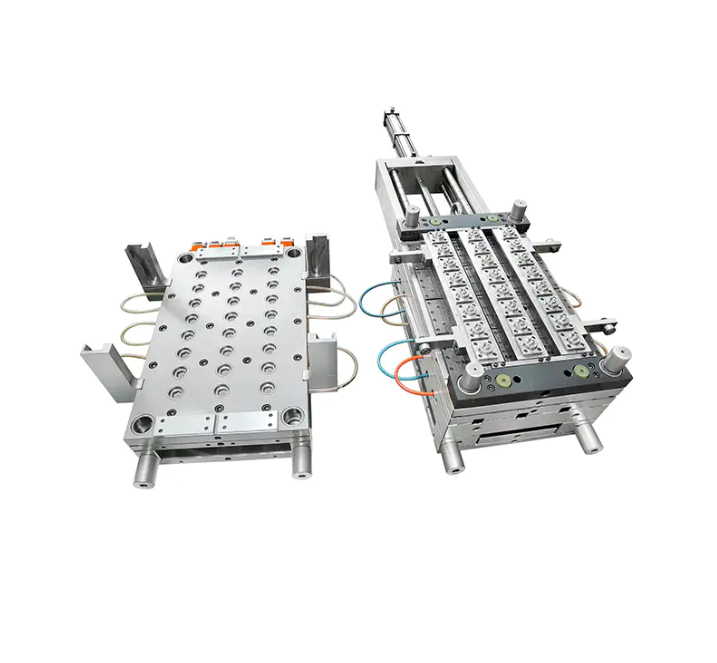

Multi-cavity cap compression machines utilize multiple mold cavities to produce several bottle caps simultaneously in a single cycle. This configuration significantly increases output and reduces the time required to achieve large-scale production targets. Advanced synchronization mechanisms ensure each cavity receives equal material flow, uniform compression, and balanced cooling, minimizing variations between caps. As a result, manufacturers can achieve a high degree of consistency in cap dimensions, sealing performance, and surface quality, which is crucial for brands striving for uniformity on packaging production lines.

One of the key technological advancements in modern multi-cavity machines is the integration of computer-controlled monitoring systems. Sensors continuously measure cavity pressure, temperature, and cycle duration, allowing operators to make real-time adjustments to maintain conditions. This monitoring ensures that each cap meets precise specifications even under high-speed production. In addition, advanced control systems can automatically compensate for minor deviations, maintaining uniformity across all cavities and reducing material waste.

Material handling has also evolved alongside machine design. Modern multi-cavity systems often employ optimized polymer flow channels and dynamic pressure regulation to accommodate a range of resin types, from high-density polyethylene (HDPE) to biodegradable polymers. These improvements prevent defects such as voids, warping, or uneven wall thickness, which are critical for maintaining the structural integrity of caps used for sealing beverages and pharmaceuticals. By controlling resin behavior within each cavity, manufacturers can produce high-quality products at scale without sacrificing precision.

Another major advancement is the adoption of modular and quick-change mold designs. Multi-cavity machines now allow faster mold replacements or cavity reconfigurations, minimizing downtime and enabling manufacturers to switch between different cap sizes or designs efficiently. This flexibility is particularly valuable for companies producing multiple product lines, limited editions, or seasonal packaging, which must adapt quickly to market trends. Modular designs also simplify maintenance, as individual cavities can be serviced without shutting down the entire machine.

Automation and robotics further enhance multi-cavity system performance. Robotic arms handle material feeding, cap removal, and quality inspections, streamlining operations and reducing human error. Integrated vision systems or AI cameras can detect defects in real time, enabling immediate corrective actions. These automated workflows improve operational efficiency and help ensure consistent quality in high-volume production.

Energy efficiency is another area of improvement. Multi-cavity cap compression machines now utilize servo-driven systems, low-friction components, and optimized heating and cooling cycles to reduce power consumption per cap. This focus on efficiency aligns with sustainability goals, lowering operational costs while minimizing environmental impact.

Taizhou Chuangzhen Machinery continues to in these innovations, constantly refining multi-cavity cap compression machines. By combining precision engineering, intelligent control systems, and modular mold designs, the company provides manufacturers with high-yield, flexible solutions that meet the rigorous demands of modern packaging production.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.