chuangzhen@capping-machine.net

EN

In modern manufacturing environments, where beverage, pharmaceutical, and personal care products are produced in high volumes, the Capping Machine has become an essential component of the packaging line. Its role is to ensure that every bottle, vial, or container is securely sealed, maintaining product integrity and shelf stability. Behind this routine operation lies a combination of precise mechanics, intelligent controls, and speed optimization. High-speed rotary capping machines, in particular, have established themselves as the benchmark for manufacturers seeking consistent sealing performance, efficient production, and reliable operation.

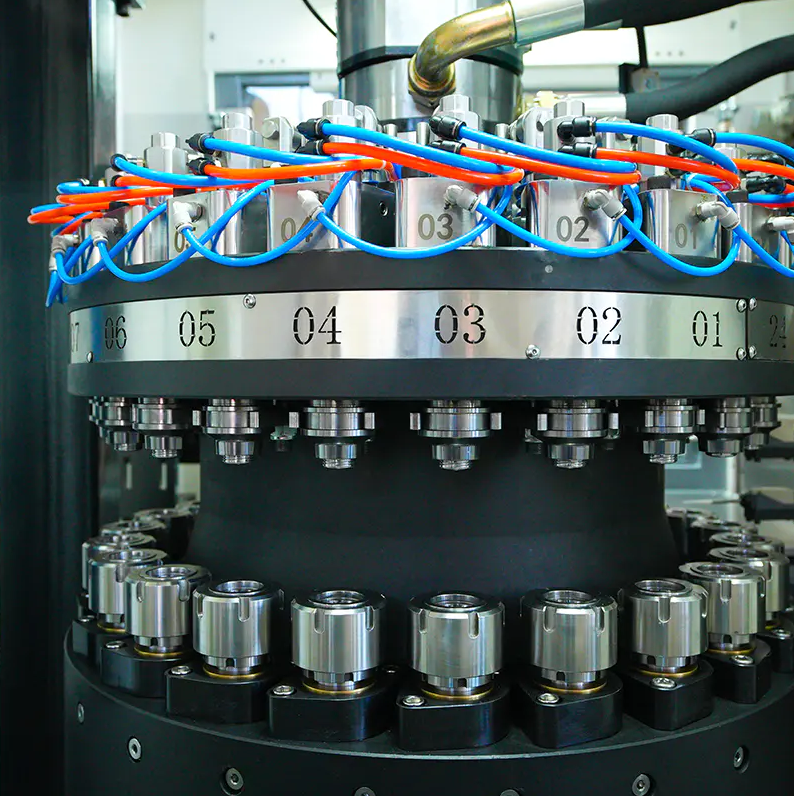

High-speed rotary capping systems are designed for continuous motion, allowing multiple bottles to be sealed simultaneously as they pass through the turret’s capping heads. Each spindle applies accurate torque to secure the cap without damaging the threads or bottle neck. This synchronized motion ensures smooth, uniform production while preventing leakage and maintaining product safety. In high-output environments where millions of bottles move along production lines daily, such precision reduces material waste and supports operational efficiency.

The beverage industry represents one of the largest applications for rotary capping technology. From carbonated drinks to bottled water, these machines provide airtight seals that withstand internal pressure fluctuations and transportation stresses. Servo-driven torque heads automatically adjust to bottle types and cap materials, minimizing human intervention and production interruptions. Real-time sensors monitor torque and cap alignment, allowing immediate correction if deviations occur. This level of control enables beverage manufacturers to scale operations while ensuring product quality and consistency across multiple markets.

In pharmaceuticals, capping accuracy is critical for safety. Medicines, vaccines, and other health products must be securely sealed to prevent contamination or tampering. Rotary capping machines in this sector often feature sanitary stainless-steel construction, fully enclosed systems, and precise torque monitoring. Many units integrate vision inspection modules to detect misaligned, loose, or missing caps instantly. These technologies support compliance with GMP and FDA standards while safeguarding product integrity throughout filling and distribution. Maintaining sterile conditions and repeatable torque application ensures both safety and regulatory reliability.

The personal care and cosmetics industries demand both flexibility and precision. From glass perfume bottles to plastic pump dispensers, product diversity requires rapid changeovers and gentle yet firm closure of various cap types. Modern rotary capping machines achieve this with quick-change tooling, servo-controlled motion, and programmable settings. Operators can switch between bottle formats within minutes, reducing downtime while maintaining a smooth production flow. Gentle torque application prevents scratches or deformation on decorative or metallic caps, preserving product aesthetics and supporting brand perception.

Recent technological advancements have introduced smart automation to rotary capping systems. Integration with IoT and intelligent control platforms allows real-time data collection and predictive maintenance. Machine learning algorithms analyze torque profiles, vibration patterns, and production rates to anticipate component wear before issues arise. This proactive approach minimizes unplanned stoppages and optimizes energy usage across packaging lines. When connected to a broader manufacturing execution system (MES), rotary capping machines become part of a transparent, data-driven production ecosystem that supports informed decision-making and cost control.

Energy efficiency and sustainability have also influenced machine design. With growing attention to carbon footprint reduction, modern rotary capping machines utilize servo motors, regenerative drives, and lightweight materials to lower energy consumption. Transitioning to eco-friendly or recyclable caps requires precise torque management to maintain sealing integrity. Manufacturers now prioritize designs that balance high performance with environmental considerations, aligning machine engineering with global sustainability objectives.

Reliability and mechanical endurance remain fundamental to high-speed capping technology. To meet continuous production demands, manufacturers focus on durable components, precision engineering, and long-term alignment stability. Automatic lubrication systems, sealed bearings, and advanced torque calibration maintain smooth operation over extended periods. Ongoing quality checks and intelligent feedback loops ensure consistent performance, even during sustained high-speed production.

At the forefront of these developments, Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. specializes in precision rotary capping solutions. The company integrates advanced servo control systems, modular components, and energy-efficient designs into each model, ensuring stable performance and adaptability across diverse packaging formats. With years of technical expertise and ongoing investment in intelligent automation, Chuangzhen’s rotary capping machines serve beverage, pharmaceutical, and cosmetic manufacturers, supporting high-efficiency, precise operations and advancing packaging technology across multiple industries.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.