chuangzhen@capping-machine.net

EN

In the evolving field of packaging production, efficiency, precision, and adaptability play a central role in staying competitive. The Rotary Cap Compression Moulding Machine combines mechanical accuracy with continuous operation to deliver a refined approach to cap manufacturing. This advanced system meets increasing quality demands without compromising production speed or operational flexibility.

Traditional injection moulding often relies on high-pressure techniques to fill complex moulds, which may introduce material stress, uneven thickness, and increased waste. Compression moulding takes a different approach—preheated plastic material is placed directly into the mould cavity and pressed into shape, eliminating unnecessary backflow and reducing excess use of material.

This method enables consistent material distribution without depending on pressure-based injection. As a result, manufacturers benefit from reduced defects, improved dimensional stability, and fewer quality control issues, particularly when managing high-volume production with strict specifications.

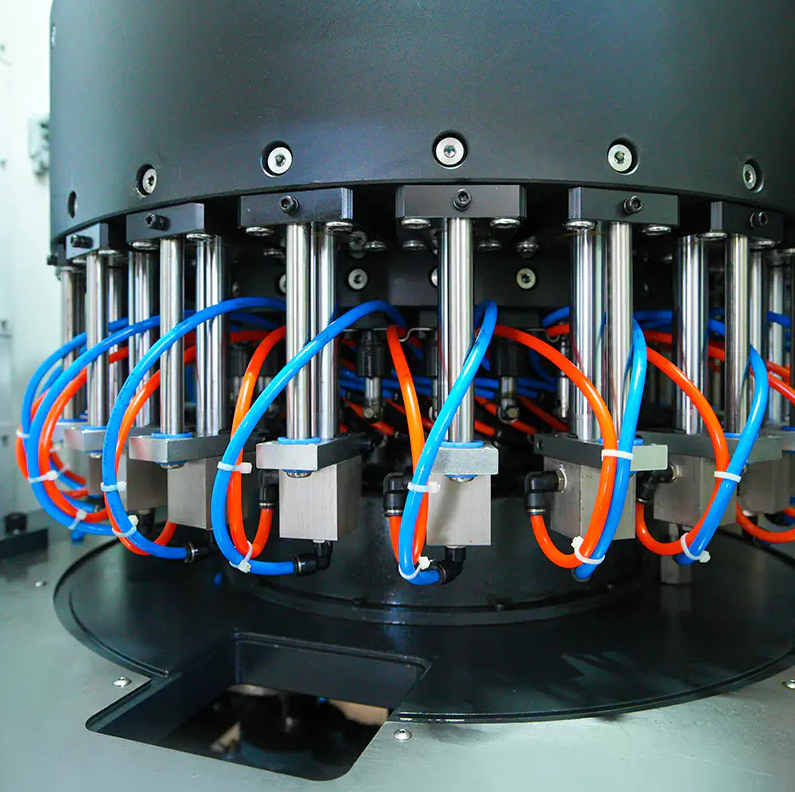

Unlike linear machines that operate in stop-and-go sequences, rotary systems work through synchronized motion. Each stage—material feeding, compression, cooling, and ejection—takes place at a separate station, rotating smoothly around a central axis. This setup enables simultaneous moulding of multiple caps, supporting a continuous flow that improves operational efficiency.

Beyond speed, rotary platforms minimize mechanical wear by reducing idle time between cycles and lowering energy consumption. The repetitive, stable movement promotes extended runtime and smoother transitions between production shifts. For factories balancing large output requirements with dependable machinery performance, this design delivers measurable advantages.

Modern cap production increasingly depends on intelligent systems with built-in automation. Advanced rotary equipment integrates each stage of the moulding cycle—from cap feeding to compression, cooling, and ejection—into a fully automated workflow. These systems use digital monitoring and real-time adjustment capabilities to optimize pressure, temperature, and cycle duration.

Adaptive feedback loops allow self-correction for minor deviations, minimizing interruptions and keeping product consistency high. Sensor-based monitoring alerts operators to wear or irregularities, while remote diagnostics and IoT connectivity support centralized oversight across multiple lines. This combination of smart control and mechanical engineering helps maintain output with limited manual input.

One of the key benefits of rotary compression technology is the ability to mold several caps in parallel. Unlike injection systems limited by cooling time and mould structure, rotary compression allows continuous operation with each cavity performing a separate function. As one cavity is being filled, another is cooling, and another is ejecting.

This layered functionality enhances cycle efficiency, helping to meet production deadlines, especially during periods of increased demand. The higher part-per-minute output contributes to stronger throughput without increasing energy draw or complexity.

A defining advantage of compression systems is their compatibility with various cap styles. Whether manufacturing flat beverage caps, flip-top closures for personal care, or custom pharmaceutical lids, the equipment supports different shapes, diameters, and thread types with minimal retooling.

This flexibility reduces downtime when switching between product lines, allowing quick adaptation to changing customer needs. Some models also support the use of sustainable materials or lightweight resins, helping businesses align with eco-conscious goals without modifying the machine’s core configuration.

As industries continue to demand flexible production capabilities and streamlined operations, the rotary compression platform delivers a reliable and scalable solution. With intelligent automation, multi-cavity design, and customizable mould support, Taizhou Chuangzhen Machinery Co., Ltd. empowers manufacturers to expand their product range and enhance long-term production efficiency.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.