chuangzhen@capping-machine.net

EN

In modern production lines, precise coordination between speed, reliability, and consistency is essential. The capping machine plays a vital role in maintaining smooth operations, positioned between upstream filling and downstream packaging processes. It ensures consistent quality from production through delivery while supporting operational efficiency and product integrity.

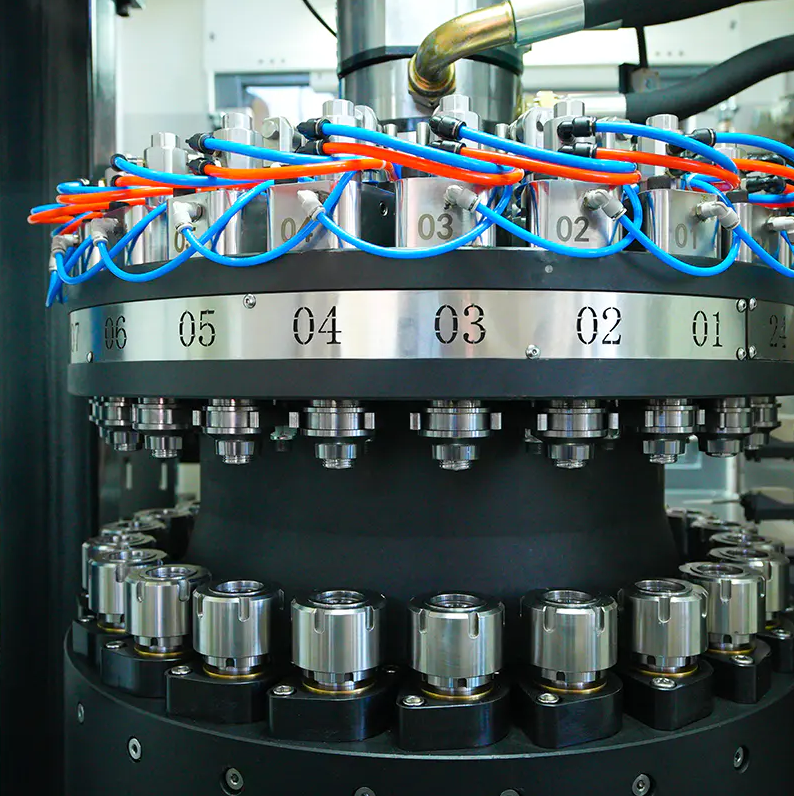

A key value of advanced packaging lines is their ability to seamlessly handle a range of product types and packaging specifications. This sealing equipment is designed with adaptability in mind, applying uniform torque to each container and minimizing inconsistencies commonly found in manual or semi-automated setups. Whether working with plastic screw closures, aluminum seals, or flip-top lids, the system secures each cap evenly without compromising the container's structure. This helps reduce leaks, prevent over-tightening, and limit damage during handling or distribution.

Its capabilities extend well beyond a single sector. In beverage bottling, it preserves freshness by securing still or carbonated liquids inside plastic or glass containers. The cosmetics industry relies on it to apply precise sealing pressure to fragile cream jars or fine mist sprayers. Pharmaceutical facilities benefit from its ability to meet hygiene expectations, supporting tamper-evident closures and protective seals. Even manufacturers of industrial cleaning agents or chemicals can rely on its dependable leak prevention when handling corrosive or viscous substances.

Another benefit is the modular design approach, which enables easy integration with upstream and downstream systems like filling stations, conveyors, or labeling machines. With adjustable mechanisms, operators can quickly transition between containers of various heights, cap sizes, and feeding methods without extended downtime. Some units feature automatic cap feeding systems, reducing manual tasks and increasing efficiency. Others include inspection modules that verify proper sealing and remove improperly capped containers, helping maintain a consistent production standard.

Installation is made more accessible by intuitive design. The interface includes a control panel that allows fine-tuning in real-time. Adjustments to torque, timing, and conveyor speed synchronization can be made quickly, reducing the training period for new operators. Visual indicators and built-in alerts help detect misalignments or faults before they affect product output.

From a maintenance standpoint, the system's internal components are designed for easy access. Routine cleaning, lubrication, and part replacement can be performed without the need for specialized tools, minimizing downtime and lowering reliance on external technical services.

As global priorities shift toward energy efficiency and environmentally conscious production, sealing systems have evolved accordingly. The materials used in critical components often support recyclability or extend operational life, helping reduce the frequency of replacements. Efficient motor performance and power regulation also align with energy-saving objectives, allowing businesses to pursue sustainability goals without sacrificing functionality.

In today's market, packaging does more than contain a product—it reflects brand quality, ensures safety, and influences the customer experience. Precision sealing is therefore an essential element of production, not just a mechanical task. Beyond the machine itself, the availability of ongoing service and support enhances long-term value. Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. offers documentation, onsite training, and spare parts assistance, helping customers simplify integration and maintain performance over time.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.