chuangzhen@capping-machine.net

EN

What is a Rotary Cap Compression Moulding Machine?

A rotary capping machine is an industrial device specifically designed for the efficient and stable forming, sealing, and securing of bottle caps onto containers. Unlike traditional capping systems that screw pre-made caps onto bottles or jars, it integrates the cap forming and compression process into a continuous operation. Through precise alignment, pressure control, and automated motion, it ensures that each container receives a well-sealed and uniformly formed cap.

Industries That Rely on Rotary Cap Compression Moulding Machines

Rotary bottle cap compression molding machines have become an essential part of modern packaging operations in various industries.

In addition, the rotary mechanism’s continuous motion supports high production volumes, which is important for beverage manufacturers operating under tight schedules. Whether it’s sealing plastic bottles, jars, or drink containers, the machine ensures uniform capping that enhances consumer confidence in both quality and safety.

Furthermore, the smooth operation and controlled compression reduce the risk of contamination, making these machines suitable for sensitive medical products, supplements, and nutraceuticals. Their ability to handle different cap materials and closure styles supports the industry’s diverse packaging requirements.

The machines’ ability to maintain consistent torque and alignment makes them suitable for luxury and customized packaging, where even slight imperfections can affect brand perception. Whether used for small-batch boutique products or large-scale commercial lines, rotary compression systems offer the reliability and flexibility that beauty brands need.

In these applications, ensuring a tight, spill-proof seal is critical to worker safety and product longevity. The consistent compression mechanism minimizes leaks and prevents external contamination, maintaining both operational efficiency and workplace safety. The adaptability of the machine also supports varying container materials and closure types used across different chemical formulations.

This technology ensures that every container is properly sealed, preventing spillage during transportation and maintaining product integrity on store shelves. For manufacturers operating diverse product lines, the ability to adjust quickly between different cap and bottle designs is an added advantage.

By ensuring accurate compression and tight closures, these machines support the safe handling of potentially sensitive or hazardous materials. Their efficiency also allows producers to meet the demand for eco-friendly and sustainable packaging options that align with modern agricultural practices.

Main Objectives of Rotary Cap Compression Moulding Machines in Packaging Lines

Rotary bottle cap compression molding machines ensure that each bottle cap is precisely formed, sealed, and secured, meeting the requirements of industrial packaging.

During the process, plastic material is compressed and shaped directly into a finished cap, eliminating unnecessary steps such as reheating or cutting. This streamlined approach reduces material waste and energy consumption, contributing to more sustainable and cost-effective production. The result is a perfectly shaped cap that meets precise specifications required for various container types used across industries.

The rotary mechanism applies uniform compression force to ensure each cap achieves a tight, reliable seal. This process maintains the balance between sealing strength and easy consumer usability, ensuring that caps remain secure during transport but are convenient to open when needed. The consistent compression also helps prevent deformation, ensuring that every closure aligns correctly with its container threads or snap-fit design.

By integrating seamlessly into automated production lines, rotary machines reduce downtime and manual intervention. This not only boosts productivity but also lowers operational costs, making them suitable for high-volume packaging environments where time and consistency are critical.

The continuous compression and forming process eliminates the need for excessive handling, reducing opportunities for contamination. This hygienic approach ensures that each cap meets strict safety and quality requirements before being used in packaging sensitive or consumable products.

This precision ensures that every cap has uniform thickness, strength, and flexibility, which helps prevent operational issues such as leakage, misalignment, or cracking. The repeatable performance of these machines supports continuous quality control, ensuring that every production run meets industry standards.

Their flexibility allows manufacturers to respond quickly to market trends — whether producing lightweight, eco-friendly caps or specialized closures for premium products. This adaptability enhances production versatility, making it possible to accommodate multiple product lines within the same facility.

Furthermore, because caps are formed directly from pellets with minimal waste, material utilization is optimized. The combination of reduced energy input and higher output efficiency contributes to a more responsible and environmentally conscious production process — a growing requirement in today’s global packaging industry.

How Does a Rotary Bottle Cap Compression Molding Machine Work?

The rotary bottle cap compression molding machine achieves its objectives through a continuous, high-precision process, combining rotary motion, sequential compression, and a quality control system to form bottle caps.

Rotary Motion and Sequential Compression

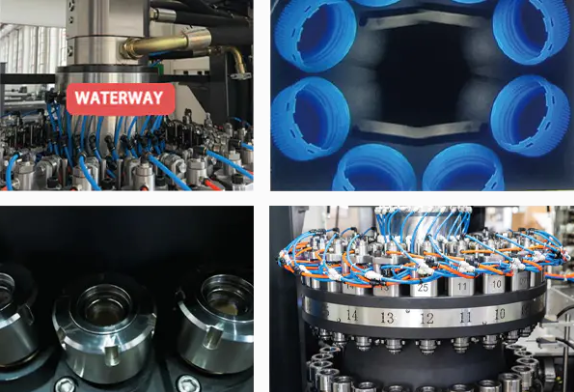

At the core of the rotary cap compression molding system is its continuous motion mechanism. The process begins with a rotating disc equipped with multiple compression stations, each acting as an individual molding unit. As the disc rotates, molten polymer material is precisely metered into each station.

Each mold cavity closes in sequence, applying consistent pressure to compress the material into the desired cap shape. This rotational motion allows multiple molds to operate simultaneously, ensuring that as one set of caps is being formed, others are cooling or ejecting — maintaining uninterrupted production. This sequential approach optimizes cycle time and ensures a smooth workflow with minimal vibration or mechanical stress.

Bottle Cap Conveying and Positioning

Once the caps are formed, the machine’s conveying system transfers them through various processing stages. Specialized conveyors or robotic arms ensure precise positioning for cooling, inspection, or downstream handling.

During this stage, temperature control plays a key role in preserving the integrity of each cap. The cooling process stabilizes the cap’s final shape and ensures it retains the proper flexibility and strength required for effective sealing. This consistent handling prevents deformation and supports dimensional accuracy, which is essential for compatibility with bottle neck threads or snap closures in subsequent packaging stages.

Compression Molding Process

The compression molding phase is the core of the system. Unlike injection molding, which forces molten material into a closed cavity, rotary compression molding introduces the material directly into an open mold. Once the material is deposited, the upper part of the mold closes and applies pressure to compress it into the desired form.

Because the material is shaped through compression rather than flow, internal stress and warping are minimized. This results in caps that are lighter yet durable, with improved sealing characteristics. Additionally, the process allows for uniform density distribution throughout the cap structure, improving mechanical performance and overall product quality.

The consistent compression also eliminates air entrapment, ensuring smooth surfaces and precise edges — factors crucial for both aesthetic appeal and functional reliability. The continuous rotary movement enhances process efficiency, maintaining a steady production rhythm with minimal operator intervention.

Quality Verification and Consistency Control

To maintain the high standards required in modern packaging, rotary cap compression molding machines integrate advanced quality control systems. As caps exit the molding section, they are automatically inspected for dimensional accuracy, shape consistency, and surface smoothness.

Sensors and monitoring units track critical parameters such as pressure, temperature, and timing throughout each cycle. This data-driven control ensures every cap produced meets exact specifications and performs reliably during sealing and consumer use. Defective caps, if any, are automatically rejected, ensuring that only compliant products proceed to the packaging stage.

Moreover, torque consistency is a critical factor in cap production. By maintaining stable compression pressure and precise mold alignment, these machines ensure that every cap provides a reliable seal without over-tightening or loosening during application. This precision contributes directly to product safety and shelf-life performance, particularly in industries such as food, beverages, pharmaceuticals, and cosmetics.

What Are the Main Components and Functions of a Rotary Bottle Cap Compression Molding Machine?

Materials are guided through a controlled path using conveyors or vibratory feeders that ensure even distribution and orientation. The design allows for continuous operation, minimizing downtime and maintaining uniform feeding speed.

An accurate feeding mechanism ensures that every mold cavity receives the proper amount of material, preventing waste and maintaining consistency in cap thickness and density. This stage also plays a critical role in avoiding mechanical interruptions, ensuring that each compression cycle begins smoothly and predictably. By maintaining a steady material flow, the feeding system contributes directly to overall process stability and production efficiency.

This stage transforms the raw material into a finished product through a balance of heat, pressure, and timing. The rotary motion allows multiple molds to operate simultaneously, enabling a continuous cycle of filling, compressing, cooling, and ejecting.

Compression molding achieves dimensional accuracy and uniform material distribution. By shaping the material through compression rather than flow, the process reduces internal stress and improves the physical strength and sealing reliability of the cap. The consistent mechanical pressure ensures that each cap is uniform in weight and structure, which is vital for both performance and compatibility with automated filling lines.

The torque control system fine-tunes the pressure applied during compression, preventing over-tightening or under-forming. Proper torque balance ensures the caps provide an effective seal without damaging the closure or container during use.

Meanwhile, the quality monitoring system employs sensors and data collection units to track variables such as temperature, compression force, and cycle timing. This real-time monitoring enables operators to detect potential deviations instantly and make adjustments when necessary. The result is consistent product quality and minimal production waste.

In modern packaging environments, these smart control systems also contribute to traceability — allowing every cap’s production data to be recorded and reviewed, ensuring compliance with manufacturing standards and enhancing operational transparency.

The conveyor ensures a smooth, continuous transition between stages, minimizing manual handling and potential contamination. Its precise synchronization with the molding unit ensures that every finished cap is efficiently transported without deformation or delay.

In addition to physical transportation, the conveyor system supports integration of the rotary compression machine into broader production lines. It allows seamless connection with filling stations, labeling systems, and packaging units. This integration supports end-to-end automation, improving workflow efficiency while maintaining product hygiene and consistency.

By connecting mechanical, electrical, and data interfaces across systems, the conveyor mechanism effectively turns the rotary compression machine into a central component of an intelligent, automated packaging line.

What Are the Differences Between This Method and Traditional Capping or Manual Sealing?

The differences between rotary bottle cap compression molding and traditional capping or manual sealing methods are rooted in technology, consistency, and production efficiency.

Traditional capping and manual sealing rely heavily on mechanical torque application or human labor to fasten caps onto bottles. In manual operations, workers apply caps individually, which can to inconsistent tightening, variable sealing strength, and slower output rates. Even in semi-automated or mechanical capping systems, torque variations and misalignment can occur due to wear, vibration, or inconsistencies in the cap and bottle dimensions. These issues can result in quality fluctuations, potential leakage, or contamination during storage and transport.

In contrast, rotary cap compression molding integrates molding and sealing into a continuous, automated process. Instead of screwing or pressing pre-formed caps, this method forms each cap from raw material within precision molds, then transfers them directly for application. The rotary motion allows multiple molds to operate simultaneously, maintaining constant production flow. The sequential compression process ensures that each cap is formed under uniform pressure and temperature conditions, providing consistent density, sealing integrity, and structural strength.

A key distinction lies in how quality control is achieved. Traditional methods often rely on post-process inspection, which identifies defects only after sealing. Rotary compression molding incorporates real-time monitoring systems that track torque, pressure, and alignment parameters during each cycle. This ensures every cap meets the required sealing standards before leaving the production zone. As a result, waste is minimized, and defective caps are immediately removed from the line.

Another distinction is efficiency. Manual and mechanical capping lines typically require multiple stations for feeding, tightening, and inspection, which can increase setup time and maintenance demands. Rotary compression molding machines streamline these steps into one continuous operation, reducing downtime and labor dependency. The result is a faster production cycle and lower operational cost per unit.

From a materials standpoint, rotary molding allows greater flexibility. Traditional capping systems depend on pre-formed caps, limiting design innovation and material optimization. Compression molding can adapt to various resin types and lightweight formulations, supporting sustainability initiatives and custom cap geometries. This adaptability enables manufacturers to produce caps that align with evolving packaging designs and consumer expectations without retooling entire lines.

Hygiene and safety are improved through automation. Manual capping exposes products to potential contamination from human contact, while rotary systems operate in closed, controlled environments. Reduced handling improves cleanliness and enhances worker safety by minimizing repetitive strain and exposure to fast-moving machinery.

Advantages and Benefits of Rotary Bottle Cap Compressors

Increased Production Efficiency and Output

The rotary design allows multiple molds to operate simultaneously, enabling continuous cap forming and ejection. This minimizes downtime between cycles, maintaining a stable production process. It achieves smooth operation, high output, and reduced delays.

Stable Sealing Quality with Reduced Errors

Each cap undergoes uniform compression under controlled temperature and pressure conditions. This precision eliminates inconsistencies often found in traditional capping or manual processes. The machine’s synchronized rotation ensures that every cap is formed to exact specifications, reducing weak seals, deformation, or leakage. The result is consistent product integrity that manufacturers can rely on across production runs.

Accommodates Various Cap Shapes and Materials

Rotary cap compression machines can be adjusted to produce a variety of designs and sizes. This adaptability makes it suitable for industries ranging from beverages and pharmaceuticals to cosmetics and industrial goods. Manufacturers can adapt to evolving packaging trends and material innovations without redesigning entire production processes.

Enhanced Hygiene and Contamination Control

Because the compression molding process operates in an enclosed system with minimal handling, there is reduced risk of contamination—important for food, beverage, and medical packaging. Automated feeding and forming systems contribute to a sterile environment, ensuring each cap meets hygiene standards.

Operational Reliability and Sustainability

Efficient energy utilization and material control reduce waste generation and operational costs. Modular construction allows easier maintenance and quick changeovers, minimizing downtime and keeping production lines running efficiently.

Industry Trends in Rotary Bottle Cap Compression Molding Machines

Rotary cap compression molding machines are a key technology in modern packaging manufacturing and continue to evolve to meet production and market demands.

Sustainable Materials and Eco-Friendly Production

Manufacturers are exploring recyclable or bio-based materials to replace conventional plastics. Rotary compression molding systems are well-suited for this shift as their process efficiently uses raw materials and minimizes waste. This aligns with global efforts to reduce carbon emissions and support environmentally responsible manufacturing practices while maintaining packaging durability.

Automation and Smart Manufacturing Integration

With Industry 4.0 developments, rotary cap compression molding machines increasingly connect to digital control systems, sensors, and real-time monitoring tools. Operators can collect performance data, identify inefficiencies, and make precise adjustments without interrupting production. Predictive maintenance features also prevent downtime, optimize operational continuity, and extend machine life.

Flexible Production Capabilities

The packaging market includes multiple cap styles, colors, and sizes for single product lines. Rotary cap compression molding machines meet this need with quick-change systems and flexible configurations, supporting small-batch custom orders, regional differences, and rapid product diversification.

Precision Sealing and Hygiene Requirements

Industries like food, beverages, and pharmaceuticals demand precise sealing and contamination control. Rotary capping machines provide a clean, enclosed operating environment and consistent molding accuracy. As safety and hygiene regulations increase, maintaining cap integrity at high volumes has become a competitive advantage.

Energy Efficiency and Resource Optimization

New-generation rotary machinery uses advanced drive systems and optimized compression mechanisms to maintain productivity while reducing energy consumption. Sustainable design supports energy conservation and environmental goals.

Global Expansion and Scalability

The expansion of packaging operations in developing regions has accelerated the adoption of rotary capping technology. Brands require equipment that is scalable, stable, and capable of handling diverse, high-volume production. Rotary capping machines offer reliable operation on such production lines.

Frequently Asked Questions

1. What maintenance practices are essential for effective performance?

Routine cleaning, lubrication of moving parts, and inspection of mold surfaces help maintain product quality and extend service life. Regular calibration of torque and temperature systems prevents performance fluctuations.

2. Can rotary compression molding machines integrate with existing production lines?

Yes. These systems can synchronize with automated filling, labeling, and packaging equipment, creating a continuous production flow. Integration enhances productivity and minimizes downtime.

3.What is the difference between rotary and linear compression systems?

Rotary machines perform compression in a circular, continuous cycle, suitable for high-volume operations. Linear machines move caps in a straight path, better for smaller or specialized production needs.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.