Our caps have a high reputation for competitive prices and high quality. We have many different kinds of plastic bottle ...

chuangzhen@capping-machine.net

EN

chuangzhen@capping-machine.net

EN

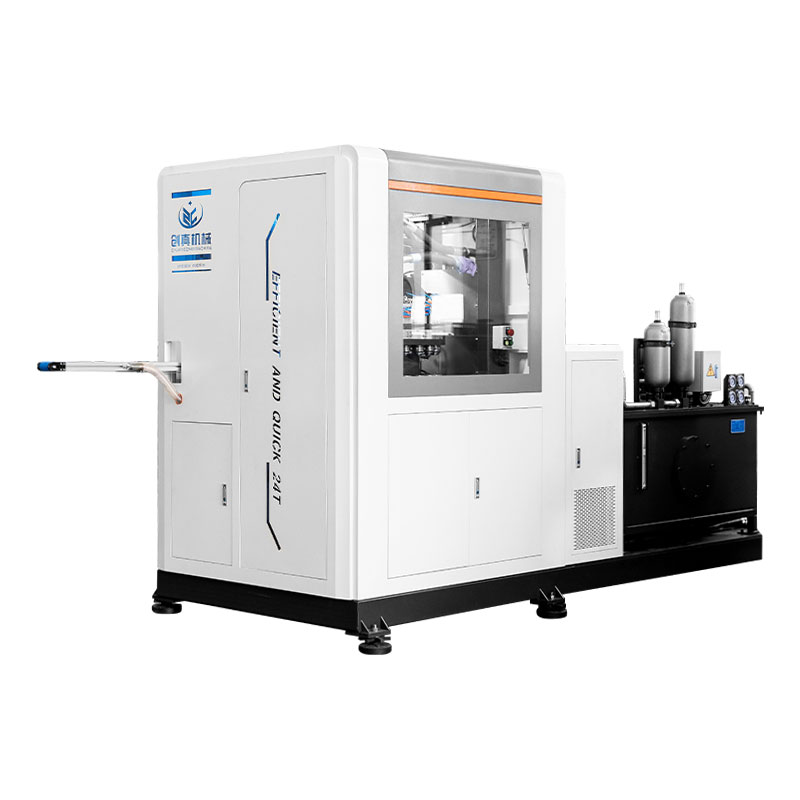

A Plastic Cap Compression Molding Machine is an advanced piece of machinery used in the manufacturing of plastic caps for bottles and containers. Unlike traditional injection molding machines, which inject molten plastic into molds, compression molding machines use heat and pressure to shape plastic materials into the desired cap design. The process is highly efficient, producing high-quality caps with excellent uniformity, precision, and strength.

These machines are used extensively across various industries such as food and beverage, pharmaceuticals, cosmetics, and household products, where high-performance, secure, and reliable caps are essential. They are designed to deliver faster production cycles and more consistent product quality compared to other methods of cap manufacturing.

Our caps have a high reputation for competitive prices and high quality. We have many different kinds of plastic bottle ...

We offer Beverage closures as well as mineral water caps and the difference is that the closures are more colorful. We k...

Profile of Products: 1. This one is the same as a glass wide-mouth jar and still keeps in high quality. FAQ 1. Why do y...

Our 24-cavity high speed cap compression machine stands as a pinnacle of efficiency and reliability in the realm of cap ...

Product Capacity

Exporting Country

Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. is a professional Plastic Cap Compression Molding Machine Factory and Supllier, main products are Capping Machine, folding machines, cutting machines, etc. The companies adhere to the "customer-oriented, forge ahead" business philosophy to provide our customers with quality service.

The company provides our customers with efficient, high-quality bottle cap production lines. Our automatic bottle cap forming machines are used to produce a wide variety of plastic bottle caps, primarily for mineral water bottles, carbonated beverages, hot juices, daily necessities, cosmetics bottles, medical supplies, edible oils, and a variety of liquor caps. The machine consists mainly of 16-48 cavities, the die is multi-purpose and simple to operate, and the machine parts and other accessories are provided by world-renowned manufacturers to ensure the stable operation of the machine so that they can truly realize their automation and high efficiency in bottle cap production. Automatic cap machines can produce up to 1,000,000 units per day, effectively saving labor and space costs, and high efficiency and energy savings benefit your short-term recovery costs and profits.

Negotiations are welcome with our company. We will provide a high-quality, thoughtful service to meet your needs.

Learn about our industry exhibition information and recent events in our company.

The recent shipment of a full high-speed production line has highlighted the manufacturing strength behind the High Speed Cap Compression Molding Machine, refl...

Capping Machine represent one of the final critical steps in many packaging lines. They apply screw caps, snap-on lids, press-on closures, roll-on bands, and va...

Bottle caps keep household cleaners from leaking onto shelves, stop garden pesticides from evaporating in the garage, and prevent brake fluid from spilling duri...

Bottle caps secure the contents of containers and allow users to open them when needed. A liner inside the cap presses against the bottle neck to form a seal th...