chuangzhen@capping-machine.net

EN

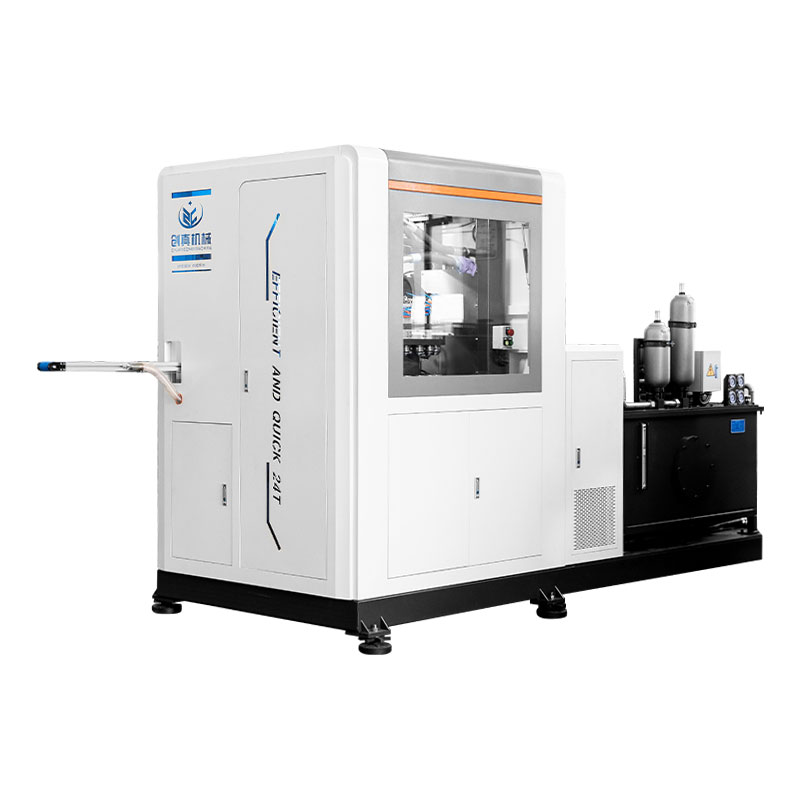

In the dynamic landscape of manufacturing, the Cap Compression Molding Machine has emerged as a cornerstone of efficiency and innovation. These machines are designed to produce plastic bottle caps with remarkable speed and precision, offering significant advantages over traditional injection molding methods.

Modern Cap Compression Molding Machines are lauded for their technical superiority. They utilize a continuous extrusion process, where plastic resin is heated and compressed directly into a mold. This method not only enhances production speed but also reduces energy consumption by up to 35-45 percent. The lower extrusion temperatures allow for faster cooling of the caps in the mold, significantly cutting down cycle times. While producing lightweight caps, the cycle time can be as short as 2 seconds, keep to higher productivity and lower operational costs.

The caps produced by these machines exhibit mechanical characteristics and homogeneity. The compression molding process results in a higher specific density of the plastic material, eliminating the stress points commonly associated with injection molding. This leads to a more durable and consistent product. The absence of injection points also ensures a smoother finish, enhancing the aesthetic appeal of the caps.

Cap Compression Molding Machines are more environmentally friendly, requiring less material and producing minimal waste. The process does not involve runners or sprues, which are typical in injection molding, thereby reducing material usage and waste. Additionally, the energy efficiency of these machines translates into cost savings, making them a financially attractive option for manufacturers.

These machines offer unparalleled versatility, catering to a wide range of applications in the beverage, dairy, liquor, condiment, cosmetics, and pharmaceutical industries. They can produce various types of caps, including those for bottled water, beverages, dairy products, liquor, condiments, cosmetics, and pharmaceuticals. The ability to quickly change colors without extensive cleaning of the hot chamber further enhances their efficiency and adaptability.

The design of Cap Compression Molding Machines ensures that the molds undergo less stress and wear compared to injection molding molds. The up-and-down and back-and-forth movements in the compression process do not affect the molds in the same way as injection molding. This results in molds that can be used for decades without deformation, significantly reducing maintenance costs and downtime.

Companies like Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. are keep the way in compression molding technology. With a professional R&D team, they are dedicated to creating value for customers through keep design and innovative solutions. Their machines are designed to offer high efficiency, high capacity, and high stability, providing good solutions tailored to customer needs.

The Cap Compression Molding Machine represents a significant advancement in the manufacturing of plastic bottle caps. Its blend of efficiency, quality, and environmental friendliness makes it an invaluable asset for industries requiring high-volume cap production.

Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. is a manufacturer specializing in the production of bottle cap compression molding equipment. Our main products are Capping Machine, Cap Compression Machine(Cap Compression Moulding Machine/Cap Compression Molding Machine), Bottle Capping Machine, and Cap Slitting Machine etc. We committed to providing its customers with efficient, stable and innovative bottle cap manufacturing solutions.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.