chuangzhen@capping-machine.net

EN

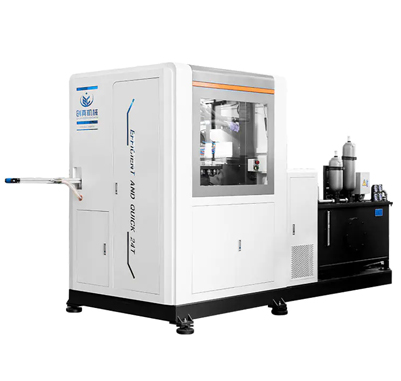

High-speed cap compression molding machines are gaining increasing attention across industries that require consistent, large-scale plastic cap production. This molding technology offers an approach that focuses on stability, speed, and efficiency in manufacturing plastic closures for bottles, jars, and containers.

Cap compression molding differs from traditional injection molding methods. In this technique, the plastic material is one melted and then precisely measured before being inserted into a mold cavity. The mold then compresses the plastic into the desired shape under controlled pressure and temperature. This process leads to less material stress and can result in better dimensional accuracy and surface finish of the caps.

When integrated with high-speed machinery, the cycle time for each molding operation is significantly reduced, allowing for a rapid and continuous output of molded caps. This is particularly useful for production lines that handle high volumes, such as beverage bottling facilities or pharmaceutical packaging centers.

One of the main attributes of high-speed cap compression molding machines is their ability to produce a large number of units per minute with reliable repeatability. These machines often feature multiple cavities — ranging from 16 to over 64 — which allows simultaneous production of numerous caps in each cycle. This contributes to enhanced throughput and shorter production timelines.

In addition, this technology supports energy-efficient operations. Because compression molding typically requires lower temperatures and pressures than injection molding, energy consumption can be moderated, potential reductions in operating costs. The machines are also engineered to minimize plastic waste by accurately controlling the amount of raw material fed into each mold.

Another important aspect is the consistent product quality. High-speed cap compression molding machines allow precise control over mold pressure, temperature, and timing, which results in caps with uniform dimensions, weight, and strength. Such consistency is crucial in applications that require sealing performance and compliance with industry standards.

High-speed cap compression molding machines are widely used in sectors where cap uniformity and large-volume production are essential. In the beverage industry, for example, caps for carbonated drinks, bottled water, and juices must be tightly produced with uniform threads and tamper-evident features. These machines can fulfill these requirements while maintaining efficiency on the production floor.

Similarly, in pharmaceutical packaging, cap integrity is vital to ensure the safety and hygiene of medical products. Compression molding machines provide a clean and controlled process, making them suitable for meeting stringent quality requirements in the pharmaceutical field.

The household and personal care sectors also benefit from this technology. Caps for detergents, shampoos, and cleaning products can be molded with customized shapes and features, enhancing usability and branding potential.

Modern high-speed cap compression molding machines are often equipped with automation features such as robotic part handling, integrated cooling systems, and real-time quality monitoring. These elements work together to reduce downtime, streamline production, and detect any deviations during the molding process. Additionally, quick mold change capabilities allow manufacturers to switch between cap designs with minimal interruption.

The adoption of high-speed cap compression molding machines represents a step forward in enhancing manufacturing efficiency for plastic closures. By combining speed, precision, and energy-conscious operation, these machines are well-suited for industries that demand consistent quality and high output. As packaging standards continue to evolve, this technology offers a reliable solution for companies seeking scalable and efficient cap production systems.

Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. is a manufacturer specializing in the production of bottle cap compression molding equipment. Our main products are Capping Machine, Cap Compression Machine(Cap Compression Moulding Machine/Cap Compression Molding Machine), Bottle Capping Machine, and Cap Slitting Machine etc. We committed to providing its customers with efficient, stable and innovative bottle cap manufacturing solutions.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.