chuangzhen@capping-machine.net

EN

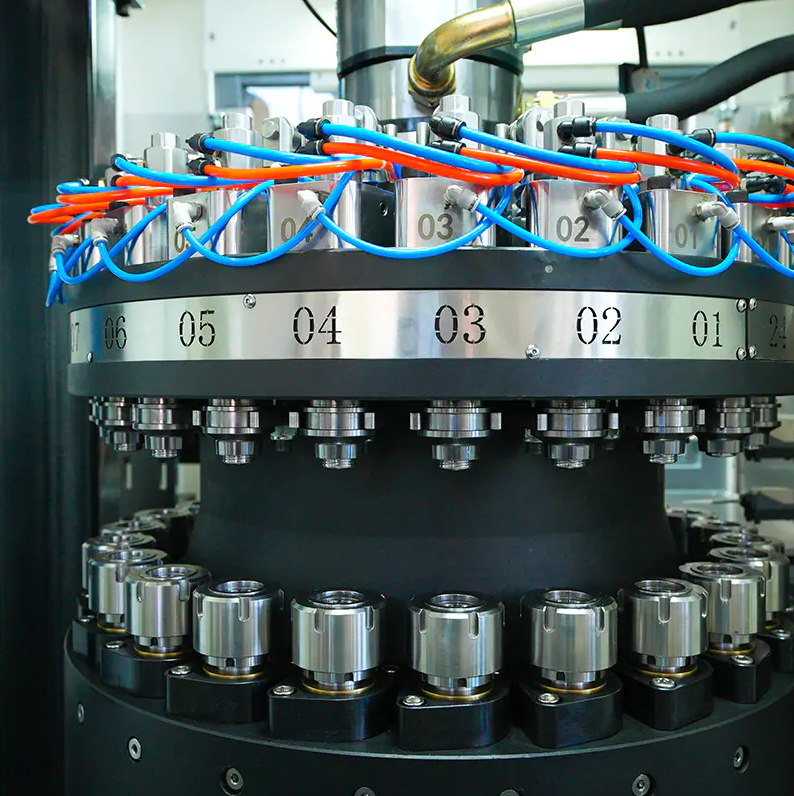

In the packaging industry, the Cap Compression Molding Machine has become an essential solution for producing high-quality plastic caps with speed, precision, and efficiency. Its advanced engineering design enables manufacturers to achieve consistent dimensions, reliable sealing performance, and strong production output. To fully utilize its potential, it is vital to understand the key components that drive its performance as well as the material compatibility that ensures long-term reliability.

Selecting the right material is as important as the mechanical design of the machine. Resin properties directly affect cap performance, safety, and sustainability.

The selected material must withstand the substances it will encounter during its intended use. For beverage caps, this means resisting the acids in juices or the carbonation in soft drinks. In pharmaceutical applications, chemical inertness ensures the cap will not react with sensitive medications.

In industrial or hazardous environments, the resin may need to resist oils, solvents, or strong cleaning agents. In such cases, HDPE or specialized engineering plastics may be favored over PP.

Combining high-performance machine components with suitable material selection can improve production efficiency and support sustainability goals. By minimizing material waste, using recyclable or bio-based resins, and leveraging automation technologies, manufacturers can achieve both operational and environmental benefits.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.