chuangzhen@capping-machine.net

EN

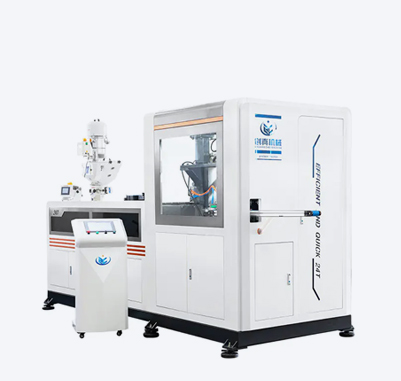

Plastic caps play a key role in packaging across industries such as beverages, personal care, and household products. To meet the growing demand for consistent quality and production efficiency, Chuangzhen Company offers a dependable range of plastic cap compression molding machines, developed through steady innovation and practical engineering.

Plastic cap compression molding machines are specialized equipment used to produce plastic caps by compressing pre-heated plastic material directly into a mold cavity. Unlike injection molding, this process uses lower temperatures and pressure, which can reduced energy consumption and consistent product quality. The machines are designed for high-speed, continuous operation, making them suitable for large-scale cap manufacturing.

Compression molding is a technique that shapes plastic caps by applying heat and pressure to plastic material inside a mold. Unlike injection molding, where molten plastic is injected into a closed mold cavity, compression molding involves placing a precise amount of plastic into a heated mold and then compressing it into shape. This method is often preferred for producing caps with uniform weight, high dimensional accuracy, and a smooth finish.

Chuangzhen’s compression molding machines are designed to support high-speed production with a stable molding process, helping manufacturers reduce material waste while maintaining product consistency.

Chuangzhen’s plastic cap compression molding machines are built with practical features tailored to the real-world needs of factories and operators. The machines generally include:

Precision Mold Systems: Each machine uses multi-cavity molds designed to ensure consistent pressure and heat distribution. This helps improve the molding accuracy of each cap.

Energy-Efficient Heating Units: Designed for stability and temperature control, the heating system ensures the material is cured properly without overheating.

Servo-Driven Components: Certain motion controls within the machine use servo motors, which improve responsiveness and reduce mechanical wear.

User-Friendly Interface: The control systems are equipped with intuitive touchscreen panels, allowing operators to monitor performance, set parameters, and identify alarms easily.

These features reflect Chuangzhen’s approach to balancing technical performance with operational simplicity.

Chuangzhen’s machines are widely used by manufacturers of beverage closures, especially for carbonated drinks, bottled water, and dairy products. They are also suitable for producing caps for edible oil, cosmetic containers, and cleaning product packaging.

Because compression molding allows for lighter cap designs without compromising strength, many packaging companies are turning to this method as part of their efficiency and sustainability efforts.

Using compression molding for plastic caps offers several advantages:

Material Efficiency: The process typically produces less flash and waste compared to injection molding.

Shorter Cycle Times: Once optimized, compression molding can achieve fast production rates while using lower temperatures.

High Cap Quality: The technique results in caps with smoother surfaces, uniform dimensions, and low stress marks.

Lower Mold Maintenance: Since there is less pressure on the mold compared to injection molding, wear and tear are reduced.

Chuangzhen has refined its machinery design to align with these strengths, while offering stable performance in long-term operation.

Chuangzhen Company provides more than just equipment. Each machine is supported with technical guidance, mold development support, and after-sales service. The company works closely with customers to adapt machine configurations to specific production needs, whether for small-scale pilot runs or larger factory installations.

Plastic cap compression molding continues to be a reliable and cost-effective method for producing high-quality caps. Chuangzhen Company, with its practical understanding of molding technology and customer needs, offers solutions that support manufacturers in maintaining product consistency, reducing waste, and optimizing efficiency.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.