chuangzhen@capping-machine.net

EN

Capping machines are now integral to modern production, supporting diverse industries from food and beverage to pharmaceuticals, cosmetics, and household goods. As packaging volumes climb and product requirements grow stricter, innovations in capping technology are fundamentally changing how containers are sealed.

Modern cappers do far more than just place caps. They bring together precision engineering, advanced automation, and smart material use to keep up with fast-paced production without sacrificing seal quality. The latest developments aim for greater speed, sharper accuracy, less material waste, and improved performance with recyclable materials.

A major challenge in packaging is achieving consistent, precise seals at high throughput. Lines often run non-stop, handling thousands of containers per hour. A faulty seal can mean leaks, contamination, or product rejects—all driving up costs.

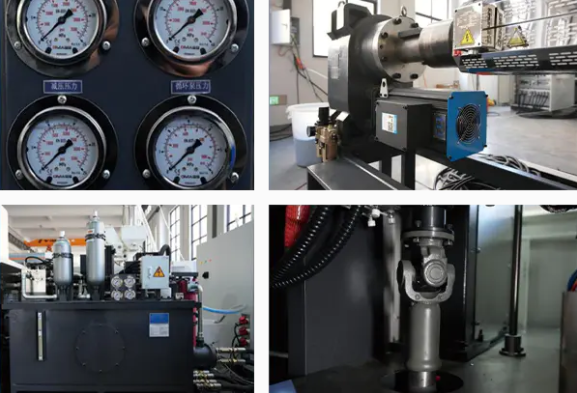

Today’s capping machines are built for rugged stability. Their reinforced frames, carefully balanced rotary parts, and refined drive systems minimize vibration even at top speeds. This solid foundation keeps bottles and caps perfectly aligned throughout the sealing process, cutting down on errors.

Precision is enhanced by smart control systems that monitor capping in real time. Sensors track cap position, bottle height, and rotational speed, allowing instant adjustments if something drifts out of spec. This is especially crucial for handling light or flexible packaging that might wobble on the line.

The result is a capper that doesn’t just go fast—it runs reliably fast. Manufacturers gain from less downtime, fewer rejects, and a smoother, more efficient packaging operation overall.

Advances in capper design are key drivers of packaging line performance. Through automation and digital integration, manufacturers can simplify processes while hitting high accuracy targets—a major advantage in facilities that frequently switch between products.

Sustainability has become a top priority in packaging, and compression molding for caps plays an important role. Applying heat and pressure inside a mold, this process improves material efficiency and strengthens support for circular economy practices.

A key benefit lies in material efficiency. When compared to conventional injection molding, the compression method often requires less raw plastic to manufacture caps of equivalent strength and reliability. This reduction in materia l use directly decreases plastic consumption. Furthermore, the resulting lighter caps contribute to lower transportation weights, enhancing efficiency across the entire supply chain.

A critical advancement is the technology's improved ability to process recycled plastics. Modern compression molding machines offer precise control over temperature and pressure cycles. This stability is essential for reliably working with recycled resin streams, ensuring the final caps consistently meet required specifications for dimensions and sealing performance.

Innovations in mold design also play a crucial role in waste reduction. Engineered for material distribution, these molds minimize excess plastic (flash) and substantially cut down on production scrap. Moreover, the clean, sprueless nature of the process means that any leftover trim or regrind material can often be reintroduced into the production cycle, pushing waste levels even lower.

Achieving the correct torque during capping is a non-negotiable factor for package integrity and user experience. An under-tightened cap risks leaks and contamination, while an over-tightened one can damage threads, deform containers, or render the product frustratingly difficult to open.

To address this, modern capping machines employ sophisticated torque-management systems. Whether utilizing mechanical torque limiters, magnetic clutches, or servo-driven mechanisms, these systems are designed to apply a consistent, predetermined rotational force to every single cap on the line.

The integration of electronic monitoring elevates this precision further. Sensors provide real-time feedback on the resistance encountered during tightening, allowing for dynamic adjustments. This capability is especially important on lines that run diverse closure types, from standard plastic and aluminum caps to more complex child-resistant designs.

To meet the colossal output demands of consumer goods, the industry has turned to parallelization. Multi-cavity and multi-head designs are now standard for high-volume production, fundamentally changing output economics. In the molding plant, a single multi-cavity mold can produce dozens of identical caps with each press cycle, slashing the per-unit production time. This principle is mirrored on the filling line by multi-head cappers, where several closures are applied simultaneously, enabling line speeds that would be impossible with a single-head machine.

This architecture offers benefits beyond sheer output. Distributing the workload across multiple stations reduces concentrated stress and wear on any single component, to more predictable maintenance schedules and longer machine life. Individual heads can often be serviced or calibrated without a full line shutdown. The central challenge—and a key technological advancement—lies in synchronization. Advanced servo controls and integrated sensor networks ensure every capping head operates in absolute unison, guaranteeing that uniform torque and alignment are maintained across every single container, proving that greater speed need not compromise quality.

Today’s capping machines have become sophisticated systems that add value well beyond sealing. They deliver stable high-speed operation, allow rapid changeovers, support sustainable materials, ensure precise torque, and multiply output using multi-cavity designs, solving many core challenges in modern packaging.

Consumer and industry expectations continue to rise, making the capper essential for achieving efficiency, quality, and responsible production. Manufacturers adopting these advanced technologies gain the ability to boost productivity, reduce waste, and maintain reliable performance across diverse packaging lines.

The capping machine plays a key role in the move toward smarter, more efficient, and sustainable packaging operations.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.