chuangzhen@capping-machine.net

EN

In the competitive field of plastic bottle cap manufacturing, selecting the right production method significantly impacts product quality, cost efficiency, and sustainability. Compared to other manufacturing techniques such as injection molding or extrusion, the Plastic Cap Compression Molding Machine has become a reliable and advantageous technology. Its unique benefits make it a choice for producing durable, precise, and cost-effective plastic bottle caps.

One of the main advantages of using a Plastic Cap Compression Molding Machine is its efficient material utilization. Unlike injection molding, which often requires excess plastic to fill complex molds, compression molding only uses a controlled amount of material pressed into the mold cavity. This precise process reduces waste, lowers raw material costs, and provides economic benefits, especially for large-scale production. Additionally, compression molding allows manufacturers to work with a wider range of thermoplastic materials, including those with higher viscosity that may be difficult to process using other methods.

The quality and durability of caps produced by compression molding are also notable. This method applies uniform pressure during molding, ensuring consistent density and structural integrity throughout the product. As a result, plastic bottle caps made by compression molding generally have higher mechanical strength, improved resistance to cracking or deformation, and smoother surface finishes. Such quality is essential for applications requiring tight sealing and reliable protection, such as food and beverage packaging or pharmaceutical containers.

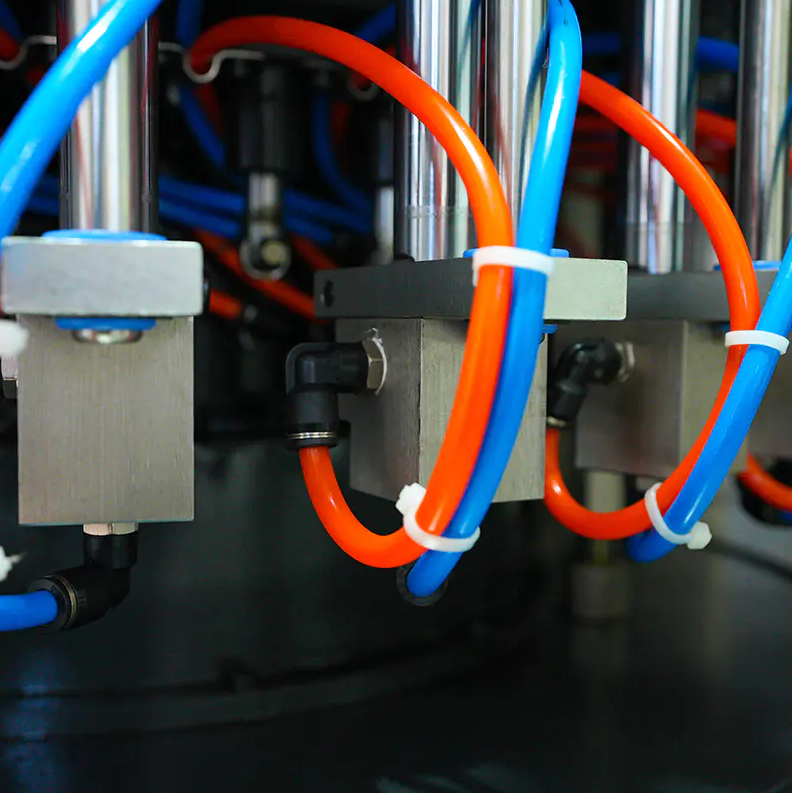

Another advantage of compression molding is its ease of operation and lower energy consumption. Compared with injection molding machines, plastic cap compression molding machines operate at relatively lower temperatures and pressures, reducing energy use. This efficiency not only cuts production costs but also aligns with the industry's increasing focus on environmentally friendly manufacturing practices. Furthermore, these machines often have fewer moving parts, simplifying maintenance and minimizing downtime.

Design flexibility is a key characteristic of compression molding. Since the process does not rely on complex gates and runners, it is easier to produce caps with varying thicknesses, textures, and sizes. This adaptability enables manufacturers to customize bottle caps according to specific customer requirements or market trends without incurring high modification costs.

In certain production settings, especially when manufacturing simple cap designs, compression molding can also shorten production cycles. Faster cooling and curing stages help increase output while maintaining product quality. Speed is critical for manufacturers who aim to scale production while upholding high standards.

The Plastic Cap Compression Molding Machine offers multiple advantages over other plastic bottle cap manufacturing methods. From efficient material use and product quality to energy savings and design versatility, this technology meets both economic and environmental demands effectively.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.