chuangzhen@capping-machine.net

EN

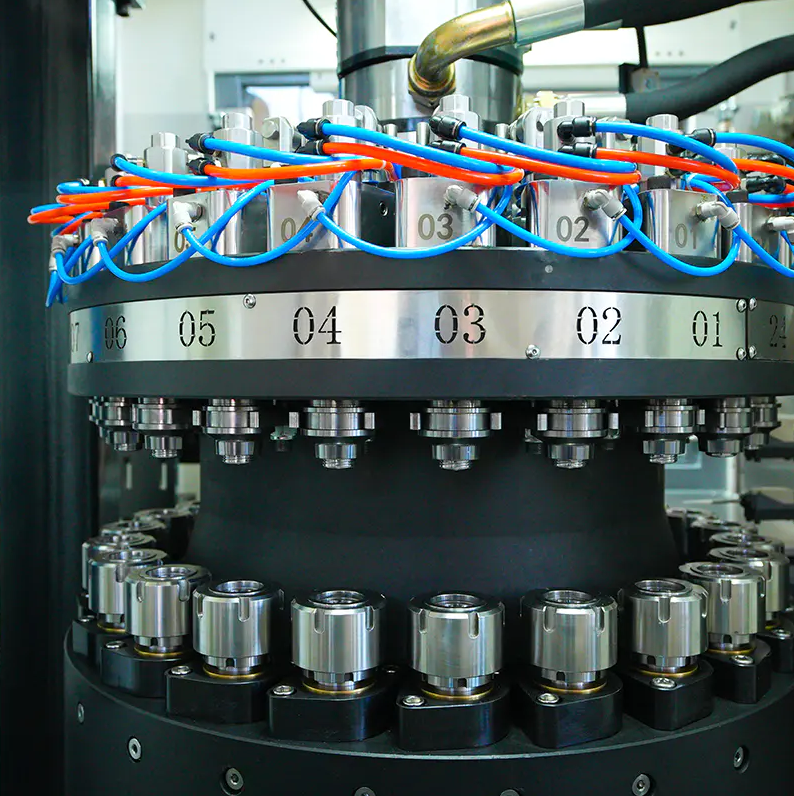

In the packaging industry, a Capping Machine is no longer just a tool for sealing containers; it has become a central solution for precision, speed, and sustainability. With advancements in smart sensors, AI-driven control systems, and automated detection technologies, modern capping solutions ensure consistent product quality while significantly reducing waste. These innovations enable manufacturers to meet the growing demand for reliable, eco-conscious, and cost-efficient packaging.

Traditional capping processes often faced challenges such as inconsistent torque, misaligned caps, or inadequate sealing, which could compromise safety and result in product defects. Modern capping machines equipped with intelligent sensors and AI algorithms address these issues by monitoring torque and pressure in real time. Servo-driven control systems adjust the sealing force with high accuracy, ensuring every cap is applied consistently on high-speed production lines.

This intelligent control not only minimizes variations but also enhances operational speed, allowing manufacturers to achieve higher throughput without sacrificing precision. By combining machine intelligence with mechanical accuracy, producers can reduce downtime, improve consistency, and lower defect rates.

Quality assurance is another key strength of next-generation capping machines. Vision systems and real-time detection tools monitor each step of the process, identifying issues such as tilted caps, improper torque application, or surface defects. Any irregularity is flagged immediately for correction or removal before products continue down the line.

This closed-loop feedback system supports higher production yields while reducing reliance on manual inspection, which can be time-consuming and prone to errors. By detecting and addressing problems early, manufacturers can minimize material waste while ensuring every sealed product complies with strict quality standards.

Precision control also brings a clear environmental advantage by reducing plastic waste. Misaligned or overtightened caps often to rejected bottles and wasted materials. Advanced capping machines minimize these errors, lowering rejection rates and conserving resources throughout the production cycle.

In addition, these machines support the use of lightweight caps, which reduce plastic consumption without compromising performance. With precise torque application, manufacturers can confidently implement lightweight designs that decrease environmental impact and material costs while aligning with sustainability goals.

Beyond material savings, modern capping machines are also designed for energy efficiency. Servo motors consume less power compared to traditional pneumatic systems, while automated calibration reduces idle machine time. The combination of intelligent energy use and precise control creates measurable resource efficiency that benefits both manufacturers and the environment.

For industries such as beverages, pharmaceuticals, and cosmetics, where production runs into millions of units, these incremental gains translate into significant cost and energy savings while ensuring consistent packaging quality.

The flexibility and intelligence of advanced capping machines make them indispensable across industries. Beverage producers rely on them to preserve freshness and prevent leaks. Pharmaceutical companies benefit from secure sealing that ensures product integrity and compliance. Cosmetic brands value their ability to maintain packaging aesthetics while reducing rework and material waste.

In every case, the ability to reduce defects, optimize efficiency, and support eco-friendly packaging strategies gives manufacturers a competitive edge in markets that increasingly prioritize sustainability and quality.

The evolution of capping technology is closely aligned with broader industry goals of automation and sustainability. Machine learning integration will allow equipment to adapt in real time to new materials and cap designs, while digital twin simulations can optimize production outcomes before physical trials. These advancements promise further improvements in defect reduction, waste management, and operational efficiency.

As these innovations continue to shape the industry, Chuangzhen Machinery provides advanced capping solutions that combine precision engineering with sustainable design. With expertise in developing reliable, high-performance equipment, the company supports manufacturers in achieving operational excellence and eco-conscious production strategies, ensuring adaptability in a rapidly changing packaging market.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.