chuangzhen@capping-machine.net

EN

As the beverage industry faces increasing pressure to reduce its environmental footprint while meeting growing production demands, sustainable packaging has become a focal point. The Cap Compression Molding Machine has emerged as a key player in this shift towards eco-friendly packaging. By enhancing production efficiency, reducing material waste, and supporting the use of sustainable materials, cap compression molding machines are helping manufacturers meet both operational and environmental challenges.

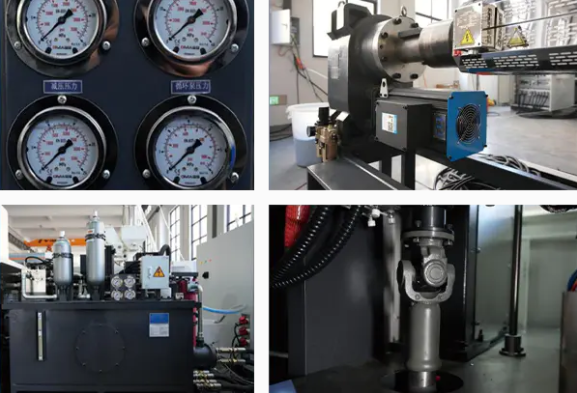

One of the primary advantages of cap compression molding machines is their ability to produce caps with unparalleled precision. Unlike traditional molding techniques, which often involve excess material and post-production trimming, cap compression molding machines apply controlled pressure and heat directly to the material. This process ensures that each bottle cap is molded to exact specifications, reducing defects and ensuring consistent quality. The precision of these machines minimizes material waste, which is a critical factor for both cost efficiency and sustainability.

Moreover, the high-speed production capabilities of cap compression molding machines ensure that manufacturers can meet growing demand without compromising efficiency. With minimal downtime and fewer defects, these machines help beverage companies maintain a steady flow of production while reducing energy consumption and waste.

Sustainable manufacturing requires the use of optimized materials, and cap compression molding machines are well-suited to this task. These machines can work with a variety of materials, including recyclable plastics and biodegradable alternatives, which helps beverage companies reduce their reliance on virgin materials. By using recycled plastics, manufacturers can lower resource extraction, reduce plastic waste, and contribute to the circular economy.

The ability of cap compression molding machines to mold biodegradable materials into functional, durable caps further supports sustainability goals. After use, these caps break down naturally, reducing the accumulation of plastic waste in landfills and oceans. This versatility makes cap compression molding machines essential in the production of eco-friendly beverage packaging.

Another key aspect of sustainability is energy consumption. Cap compression molding machines are designed with energy efficiency in mind, incorporating advanced features such as optimized heating mechanisms and automated controls. These innovations help reduce energy use without compromising the quality or speed of production. By consuming less energy, manufacturers not only reduce their carbon footprint but also lower operational costs, creating a more sustainable production process.

Furthermore, the precision and efficiency of these machines ensure that material waste is minimized. This combination of energy savings and waste reduction supports the broader goals of sustainable manufacturing while offering financial benefits to companies.

Cap compression molding machines contribute significantly to the circular economy by ensuring that the caps they produce are designed for recyclability. Caps made from recyclable materials are easier to process at the end of their life cycle, reducing waste and promoting material reuse. This aligns with global efforts to minimize plastic waste and close the loop on packaging materials.

By producing caps with minimal excess material and improving recycling rates, cap compression molding machines play a key role in driving sustainability in the beverage packaging sector. The long-lasting durability of these caps also supports the efficient use of resources, as they are less likely to require frequent replacements.

Technological advancements continue to enhance the capabilities of cap compression molding machines. With ongoing improvements in automation, precision molding, and material handling, these machines are becoming even more efficient, versatile, and eco-friendly. For example, modern machines can integrate seamlessly with automated packaging lines, reducing human error and further streamlining production processes.

As manufacturers increasingly adopt these advanced machines, they are not only improving their production processes but also contributing to the industry's move toward more sustainable, resource-efficient manufacturing practices.

TaiZhou Chuangzhen Machinery Manufacturing Co., Ltd. is committed to advancing this transformation. By producing high-quality cap compression molding machines that integrate precision engineering with sustainable design principles, Chuangzhen Machinery helps manufacturers enhance efficiency, reduce waste, and meet eco-friendly packaging goals. Their dedication to innovation and sustainability makes them a trusted partner for beverage producers worldwide, supporting a future where packaging meets demand without compromising environmental responsibility.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.