chuangzhen@capping-machine.net

EN

The demand for advanced manufacturing systems continues to grow, with efficiency and reliability shaping the success of modern production. At the center of these improvements, the Cap Compression Moulding Machine demonstrates how automation and digitalized control strategies can enhance performance while ensuring consistency across large-scale operations. Its role extends beyond single-factory benefits, influencing supply chains through faster delivery, reduced waste, and dependable quality standards.

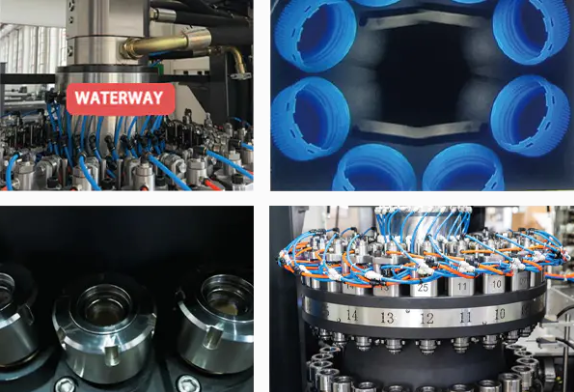

Automation has transformed the way manufacturers approach daily operations, minimizing manual errors and standardizing outputs. With a Cap Compression Moulding Machine equipped with digital control systems, operators gain real-time monitoring, predictive maintenance alerts, and the ability to fine-tune processes instantly. These features ensure every production run maintains uniformity, which is crucial in industries where product dimensions, strength, and safety must not fluctuate. By relying on automated feedback loops, manufacturers can reduce downtime while maintaining continuous operation.

Digitalization also plays a significant role in integrating machines into broader factory ecosystems. When connected to intelligent software platforms, these machines share performance data that allows managers to predict material requirements, optimize scheduling, and track quality trends. Such transparency fosters improved coordination across departments and reduces unnecessary inventory accumulation. In a competitive market, the ability to link machinery into digital networks positions companies to respond to shifts in demand more efficiently.

Another critical contribution of the Cap Compression Moulding Machine lies in its high-speed production capacity. Faster production cycles directly influence supply chain agility, allowing manufacturers to meet larger order volumes without compromising on precision. High output not only shortens times but also supports just-in-time strategies, ensuring that products reach downstream partners when required. In sectors where packaging components or closures play a vital role, such responsiveness can strengthen relationships between manufacturers, distributors, and retailers.

High-speed capability also addresses fluctuations in global demand. When markets experience sudden spikes, companies that rely on slower production lines may face bottlenecks, delayed shipments, or quality inconsistencies. By contrast, facilities equipped with advanced compression moulding machines can scale output rapidly, ensuring business continuity and customer satisfaction. This capacity is particularly valuable for multinational supply chains where delays can cascade into higher logistics costs and lost opportunities.

The integration of automation with speed further creates efficiencies in material usage. Precision control minimizes waste during the moulding process, ensuring that raw inputs are utilized effectively. In addition, predictive maintenance features reduce the risk of sudden stoppages, which could otherwise interrupt supply chain timelines. For industries that require strict cost management, such improvements provide a measurable competitive edge.

Beyond efficiency and speed, digitalized systems also strengthen traceability within the supply chain. Each batch produced by a Cap Compression Moulding Machine can be logged with detailed information, including material type, production time, and quality inspections. This traceability builds confidence among partners and clients, ensuring compliance with global regulatory requirements. It also provides the flexibility to adapt quickly if adjustments or recalls are ever necessary.

As supply chains evolve to meet the demands of global markets, manufacturers are turning to solutions that blend efficiency, speed, and reliability. The Cap Compression Moulding Machine demonstrates how modern equipment supports these goals through automation, high-speed performance, and digital integration. For companies seeking equipment that combines innovation with durability, Taizhou Chuangzhen Machinery Manufacturing offers advanced moulding solutions designed to enhance production while supporting sustainable industry growth.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.