chuangzhen@capping-machine.net

EN

Energy efficiency has become a defining factor in manufacturing technology, and the Cap Compression Moulding Machine stands out as a significant advancement that supports both productivity and sustainability. With the manufacturing sector facing growing pressure to reduce energy consumption and environmental impact, modern cap compression moulding machines offer an effective solution. By combining advanced engineering, automation, and material optimization, these machines not only lower power usage but also contribute to sustainable packaging practices, making them a key innovation for industries such as beverages, pharmaceuticals, and consumer goods.

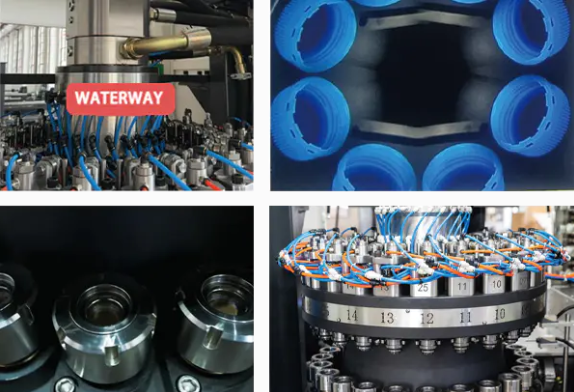

One major advantage of cap compression moulding is its ability to produce high-quality closures while consuming less energy. Advanced servo-driven systems in modern machines control movement and pressure precisely, applying energy only when necessary. This efficiency reduces the overall power consumed per unit while ensuring consistent product quality. At the same time, the faster cycle times of servo-controlled systems shorten production periods, further lowering energy requirements. This combination of speed and precision is central to both energy efficiency and sustainable production.

Sustainability in packaging goes hand in hand with energy efficiency. Cap compression moulding machines support this by enabling the use of recycled plastics and bio-based polymers, which require lower processing temperatures and pressures. This not only reduces energy consumption but also helps decrease reliance on virgin plastics, promoting a circular economy. By integrating eco-friendly materials with energy-efficient production, manufacturers can address both environmental concerns and economic demands.

The beverage industry is a prime example of where these benefits intersect. With high production volumes, even small gains in energy efficiency result in significant savings and environmental impact reduction. Cap compression moulding machines produce lightweight, durable caps while optimizing energy use, meeting sustainability goals without compromising output. Similarly, in the pharmaceutical sector, where safety and compliance are critical, these machines deliver precise closures with reduced material waste and energy consumption.

Automation plays a further role in improving efficiency. Modern machines incorporate sensors and control systems that monitor production in real time, allowing adjustments that minimize energy use. Parameters such as temperature, pressure, and cycle time can be optimized without manual intervention, reducing waste and improving reliability. This adaptability supports both energy efficiency and sustainable manufacturing goals.

Thermal management is another factor enhancing energy efficiency. Modern moulding machines are designed to minimize heat loss during production. Optimized mould designs and efficient thermal systems reduce unnecessary energy expenditure, while also prolonging machine life by decreasing wear and mechanical stress. These advantages extend the lifespan of both machinery and the closures they produce, aligning with broader sustainability objectives.

Innovation continues to drive improvements in both efficiency and sustainability. Manufacturers are exploring smart manufacturing technologies, including predictive maintenance and data-driven optimization, to further reduce energy use. The integration of these innovations ensures that cap compression moulding machines remain not only cost-effective but also environmentally responsible.

As industries increasingly prioritize green manufacturing, the role of energy-efficient cap compression moulding machines will grow. By combining reduced power consumption with sustainable material usage, these machines are shaping the future of packaging production. They represent a convergence of efficiency, environmental responsibility, and high-quality manufacturing that meets the demands of modern industry while supporting a more sustainable world.

Taizhou Chuangzhen Machinery is committed to developing high-performance cap compression moulding machines that combine precision engineering with energy efficiency and environmental responsibility. By integrating advanced technology and sustainable design principles, Chuangzhen Machinery supports manufacturers in achieving productivity goals while advancing green manufacturing practices, making it a trusted partner in the evolution of sustainable packaging solutions.

Copyright © Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. All Rights Reserved.